dm steel CNC machining

Machining method: CNC machining

Processing factory: Lianda

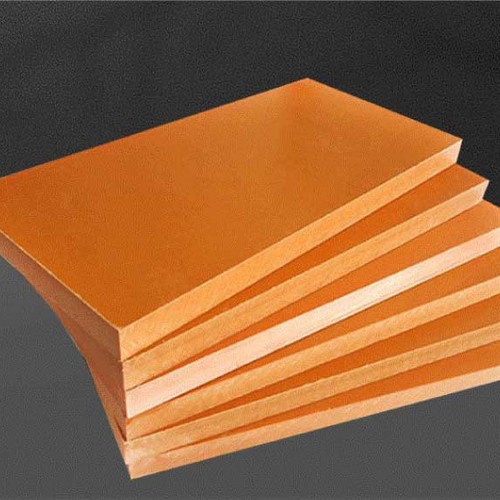

Processing material: dm steel

Processing equipment: CNC machining machine

Machining method: CNC machining

Processing factory: Lianda

Processing material: dm steel

Processing equipment: CNC machining machine

DM steel CNC machining

CNC machining of DM steel is a very important technology in the process of modern machinery manufacturing. It mainly refers to the control of the machining machine tool through the computer numerical control system, and the high-precision machining process of DM steel. In this process, some high-precision monitoring instruments and equipment are used to ensure processing accuracy and product quality. Below, we will introduce this technology from three aspects: the principle, application scenarios and advantages of CNC machining of DM steel.

DM steel CNC processing principle:

DM steel CNC machining is the use of computer numerical control system to control the machining machine tool, DM steel for various processing processes. This technology can use a variety of different machining methods and processes, such as turning, milling, drilling, grinding, and so on. In the process of machining, the computer numerical control system can automatically adjust the motion track, rotation speed and other parameters of the machine tool, so as to achieve efficient and high-precision machining process. In addition, the technology can also realize automatic replacement of workpieces and tools, greatly improving the processing efficiency and accuracy.

DM steel application scenarios:

DM steel CNC machining is mainly used in the manufacture of various precision mechanical parts, such as high-speed train parts, aircraft parts, industrial robots and their parts, medical equipment parts and so on. With the application of new materials and the continuous progress of industrial technology, CNC machining of DM steel will be used in a wider range of fields, such as aerospace, automotive, chemical and pharmaceutical.

DM steel advantages:

The main advantages of DM steel CNC machining technology are high precision, high efficiency, high reliability, high safety and so on. Its accuracy can be controlled within the micron level, maintaining the quality and stability of high-precision machining. At the same time, CNC machining has the characteristics of high efficiency and high reliability, which can greatly improve the production efficiency of products and reduce the production cycle and production costs. In addition, the technology also enables safe production, avoiding workers' exposure to intense mechanical movements and high temperature and pressure environments, thus reducing the incidence of accidents.

In short, DM steel CNC machining technology is a very important technology, has been widely used in many fields. With the continuous progress of industrial technology and the application of new materials, this technology will play a more important role in the future development.

With the continuous development of the manufacturing industry, steel processing has increasingly become an important field. Among them, one of the commonly used processing methods is CNC machining. CNC machining is characterized by high precision, fast efficiency and low cost, so it has been widely used in many fields. DM steel CNC machining is the CNC machining process of DM steel, let's take a look at it.

DM steel is a kind of precision steel, which has the advantages of high modulus of elasticity, good strength and hardness, and strong wear resistance. Therefore, it is widely used in automotive, machinery, aerospace, electronics, medical and other fields. For such a high-quality material, CNC machining is very necessary.

The main processes of DM steel CNC machining include CNC turning, CNC milling, CNC punching and so on. The use of CNC machining equipment for processing can ensure the accuracy and efficiency of the processing, and can automatically complete the processing process, save labor costs, but also reduce the error caused by human reasons.

In the CNC machining process of DM steel, the following points need to be noted:

1. Choose the right processing method. For parts with different shapes and different requirements, different CNC machining processes need to be used. For example, the outer circular parts are selected by CNC turning, the inner hole parts are selected by CNC milling, and the connected holes are selected by CNC punching.

2. Adjust the machine tool. After determining the processing method, it is necessary to set the machine tool according to the process requirements, such as the fixing of the fixture, the installation of the tool, the selection of the tool edge Angle, etc.

3. Determine the processing parameters. When processing, it is necessary to set the processing parameters reasonably, such as speed, feed speed, cutting depth, etc., to ensure the processing quality and efficiency.

4. Quality inspection. After the completion of processing, it is necessary to carry out quality inspection to verify that the processing quality meets the requirements to ensure the processing effect.

In general, CNC machining of DM steel requires a high level of technology and experience, and only after mastering the correct process methods and processing skills can the expected processing effect be achieved. Through this efficient and accurate processing method, it can effectively improve production efficiency, improve product quality and reduce production costs, so DM steel CNC machining has broad market prospects in the future.

Lianda precision focus on cnc machining, all types of materials can be, welcome to need DM steel CNC machining and five-axis CNC machining friends call to consult details