Dongguan five-axis CNC machining

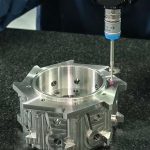

As an economically developed city, Dongguan has many industrial enterprises and manufacturing enterprises. Among them, five-axis CNC machining is a very important field. Five-axis CNC machining is based on computer numerical control technology, using mechanical cutting processing, can realize the processing of complex workpieces, with high accuracy and efficiency, is one of the important technical means in modern manufacturing industry.

In Dongguan, five-axis CNC machining has become one of the indispensable important processes in the manufacturing industry. It is widely used in aerospace, national defense, automotive, medical, electronics, mold and other industries, and has become a sharp tool to improve enterprise production efficiency and reduce processing costs. Many large enterprises have opened five-axis CNC machining workshops and introduced advanced five-axis CNC machining equipment, which provides strong support for the development of enterprises.

Dongguan five-axis CNC machining enterprises have rich experience and technology, can accurately provide customers with a variety of complex parts processing services. These services not only cover traditional machining methods such as turning, milling, drilling, planing and grinding, but also include high-end technologies such as laser cutting and electric discharge machining. Enterprises can also provide customized five-axis CNC machining services according to customer needs, such as the processing of complex workpieces, difficult processing, and high process accuracy.

In general, Dongguan’s five-axis CNC machining enterprises have considerable advantages in processing technology and equipment. They can meet the processing needs of various complex parts and components, and are always committed to improving their own technology and service levels, helping customers improve production efficiency and reduce costs, and making important contributions to the development of manufacturing.

Five-axis CNC machining is a high-efficiency and high-precision machining method, which uses numerical control technology and five-axis three-dimensional tools, which can greatly improve the processing accuracy and work efficiency of parts. Five-axis CNC machining is widely used in precision machining, such as mold, aviation, aerospace, automotive, medical devices and electronic parts industries.

The advantages of Dongguan five-axis CNC machining are:

1. High-precision machining: five-axis CNC machining adopts numerical control technology, which can be processed according to the predetermined trajectory, which can not only process parts of various shapes and dimensions with high precision, but also ensure high-precision repeatability during processing.

2. High efficiency machining: five-axis CNC machining method does not require manual operation, which can greatly improve production efficiency. More parts can be machined in the same amount of time, thus increasing production efficiency.

3. More kinds of parts can be machined: five-axis CNC machining can process more complex curved parts, with stronger processing capacity. In addition, it can also process a variety of metal and non-metallic materials, such as titanium alloy, aluminum alloy, copper, iron, stainless steel and so on.

4. Reduce the number of parts: Through five-axis CNC machining, many parts can be combined together, thus reducing the number of parts and reducing costs.

5. Environmental protection and safety: five-axis CNC machining process does not require the use of chemicals and other toxic substances, will not have an impact on the environment, but also reduce the operational risk of workers.

When using five-axis CNC machining, it is important to note that:

1. Rational use of tools: for different workpiece materials and processing requirements, different tools need to be selected to obtain better processing results.

2. Keep the equipment clean: It is necessary to keep the equipment clean and in good condition, and maintain it frequently to ensure the normal operation of the equipment.

3. Reasonable setting of processing parameters: For different workpiece materials and processing requirements, it is necessary to set processing parameters reasonably to obtain the best processing effect.

In short, Dongguan five-axis CNC machining is a high-efficiency, high-precision processing method, which has been widely used in many manufacturing industries, and provides an effective means for the manufacturing and production of parts.

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers