Three-axis X, Y and Z work and are calibrated as a three-axis CNC machine tool. The movement of the other two axes working in a five-axis machining is always controlled by a numerical control program that inputs instructions to the machine.

There are basically two types of five-axis CNC machining:

Trunnion type

When the trunnion type five-axis machine is operated, the A axis rotates around the x axis and the c axis rotates around the z axis. The rotating shaft is represented by the movement of the table. This type is more suitable for larger workloads as there is no need to compensate for the space taken up by the rotating handle.

Rotary type

Rotary five-axis machine, B axis rotates around the y axis, c axis rotates around the z axis. What makes it different is that the table is always level during the cutting process, which means it can support heavier parts. The rotating axis is represented by the rotating cutting arm.

What is the cost of five-axis CNC machining?

The cost depends on the project at hand and the number of parts being produced. In addition to the higher cost of purchasing a five-axis machine, five-axis CNC machining requires a more significant level of setup before starting production of a component. During pre-production, higher initial setup costs may reduce output or one-time costs compared to equivalent parts produced on a three-axis machine.

This is understandable because five-axis machines by their nature are more complex and dynamic than other types of CNC machines with fewer axes. Five-axis milling machines are also more time efficient because they can calibrate the finished part without any intervention. Often, only one operation is required to complete the workpiece, so downtime is greatly reduced. The requirements for fixtures are reduced, which mainly benefits more organic, complex parts.

Why are there fewer fixtures for five-axis CNC machining?

The range of motion the cutting head can achieve: The additional rotation axis means that these machines can reach five sides of a part. For example, if a geometrically complex part is needed for aerospace, a five-axis CNC machine would be the machine most capable of achieving this goal. This is due to its ability to reach complex angles and cut areas that are difficult to get, such as composite curves.

Advantages of five-axis CNC machining, high quality finish

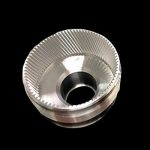

Thanks to the advanced features of the five-axis cutting tool, a higher quality finish can be achieved because the cutting tool can be shorter on the five-axis CNC machine. This reduces the vibration of the tool and, therefore, reduces the chance of flutter marks and ensures the surface finish of the final part. The need for time-consuming and expensive hand machining can be almost completely eliminated, as five-axis machines can closely follow geometric contours that are traditionally difficult to machine.

More complex shapes can be made

Five-axis CNC machining can produce very complex geometric shapes. For example, in the past, machining castings and parts containing many different characteristics required a lot of assembly to machine and complete the desired shape. However, in most cases, with only one fixture, five-axis machining can complete the precise requirements of a workpiece.

To learn more about five-axis CNC machining and how it can benefit your business, please contact us. With many years of expertise, we will give you a detailed and concise quote about your needs within 24 hours.

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

您好!Please login