What are the elements of choosing a five-axis machining center?

In this issue, we will take the industry-leading Makino five-axis machining center as an example to introduce what main factors need to be considered in choosing a five-axis machining center.

01 Structure determines device performance

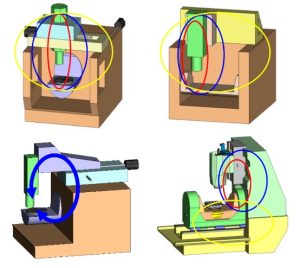

The five-axis machining center has a variety of structures, and the structural design of the machine tool determines the performance of the equipment from the basis, which determines the rigidity, processing accuracy, stability, operability and so on

The following aspects should be considered:

1) Linear axes do not merge when moving

2) The equipment with short cutting circuit has good rigidity

3) Whether the tilt rotation shaft is a DD motor

4) Whether it is 5-axis linkage

5) 5-axis proximity

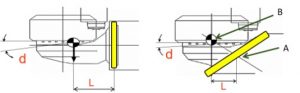

Makino’s D200Z/D800Z/a500Z series five-axis machining center adopts A “Z” type high-rigidity table structure, as shown in the following figure, the table does not need to be supported at both ends, large diameter inclined bearings, and the workpiece center of gravity B is in A. Compared with the traditional single support structure, the bending amount d is very small, and the moment arm L is shorter.

This inclined shaft structure can be achieved with the high precision processing of the 3 axis processing center. Even if loading and rotating heavy industry, the bending quantity of the workbench can also be controlled at the minimum, and high rigid bearings and direct driving motors can also realize the smooth rotation of small, high precision. There is also an excellent space approach.

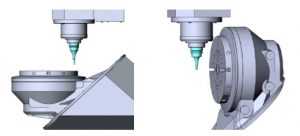

The tilted axis structure has excellent spatial proximity

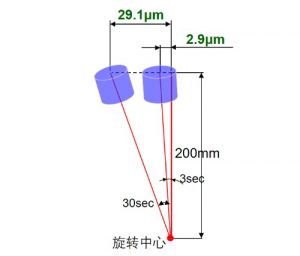

02 Tilt rotation axis accuracy

The machining accuracy of the machine tool is directly affected by the precision of the rotating axis, and the actual influence of the tilting rotary axis accuracy on the machining accuracy is understood by the Maino D800Z machine tool.

1°= 60 ‘1°= 60 “1°=3600”

The minimum resolution of the B/C axis of the D800Z machine tool is 0.0001 degree, that is, 0.36 “, and the positioning accuracy is ±3 “. Through the calculation diagram below, we can know the accuracy error generated.

03 Interference collision prevention

Interference avoidance is a problem that can not be ignored in 5-axis machining. In addition to the use of computer-side software interference inspection, Makino’s 5-axis machining center is equipped with online real-time simulation CSG function, which can prevent interference even in manual mode.

Online real-time simulation of the CSG function allows possible tooling errors or tool length setting errors to be checked prior to machining in order to minimize emergency stops in operation. In operation, the position information can be read based on the data adjusted in advance, as well as the coordinates and offset values in the CNC control device, and the possibility of interference can be predicted. Once the machine stops running, the condition screen can be displayed in real time, and the predicted involved parts and shaft direction of action can be confirmed.

04 Rotation center correction

Due to changes in the rotation center caused by changes in environment and temperature, it will affect the accuracy of five-axis machining, and it should be able to be automatically corrected by the probe, 3-axis/indexing / 5-axis machining accuracy verification processing, and tool joint error < ±4μm.

05 Linkage accuracy

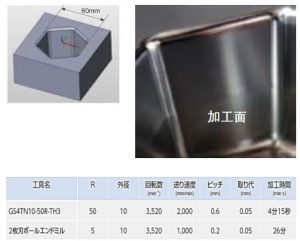

The linkage accuracy of five-axis machining center is the embodiment of multi-factor results. Taking Makino D200Z as an example, the processing cases are listed to provide linkage accuracy reference.

Processing equipment: D200ZCAM: FFCAM Workpiece material: NAK80(40HRC) Workpiece size: 140x140x35mm Cavity: clear Angle R0.22mm, depth 20mm Processing time: 1H35min/pocket tool: 7 kinds of 6

Linkage accuracy: position accuracy ±2μm, shape accuracy ±3μm

06 Process Support

The processing technology of the five-axis machining center determines whether the performance of the equipment can be maximized. For example, the special-shaped tool can greatly improve the processing efficiency.

Processing case: Efficiency increased by 6 times!

Material: YXR33(58HRC) Shape and size: as shown below, depth 30mm, drawing Angle 2°, clearing Angle R3mm

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

您好!Please login