What are the advantages of five-axis linkage processing

Five-axis machining is a high-precision, high-efficiency machining technology, compared with the traditional three-axis machining, it has many important advantages. Let’s let 3d animation production companies explore the advantages of five-axis machining.

First of all, five-axis machining can complete complex parts in a single unit. Compared with three-axis machining, five-axis machining can realize the machining of more complex work surfaces without the need for multiple repositioning of the workpiece, thus reducing the waste of time and resources in the machining process. Five-axis machining can accurately excavate and trim the surface shape of the part, especially for parts with irregular shape or curved tilt, five-axis machining can ensure the high precision of the final product.

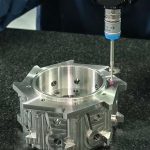

Secondly, five-axis linkage machining can be processed on multiple surfaces at the same time. The traditional three-axis processing can only process the “surface”, that is, a certain side of the workpiece, while the five-axis linkage processing can simultaneously process multiple faces, so as to achieve more processing effects in the same time period. This advantage makes the five-axis linkage machining very advantageous in the processing of complex parts, because it can efficiently process complex parts in a short time, improving production efficiency.

Third, five-axis machining has efficient and accurate control capabilities. Its control method and three-axis machining is different, combined with the quality control system, such as tracking system, real-time detection system, automatic calibration system, etc., five-axis linkage machining can adjust the processing quality in time to ensure the accuracy and quality of the product, so as to achieve more accurate and highly controlled process.

In addition, the processing accuracy of the five-axis linkage machining is higher, and the processing speed is higher, and the complex parts can be processed in a short time. This makes the five-axis linkage machining in a variety of industries required precision pa processingrts and complex surface parts processing has a very wide range of applications.

In summary, five-axis machining is one of the important technologies of modern CNC machining, it has many excellent characteristics and a wide range of application prospects, in aviation, aerospace, automotive, machinery, medical equipment and other fields have important applications.

Five-axis linkage machining is a relatively high-end technology in the field of CNC machine tool processing, and its main feature is that it can complete the processing of multiple planes under a single clamping, which greatly improves the processing efficiency and production accuracy. The following details the advantages of five-axis linkage processing.

1. A wide range of processing: five-axis linkage processing can be processed in X, Y, and Z at the same time, and can also be processed on the C axis (rotation axis) and A axis (tilt axis), making the processing range very wide, can complete a variety of complex shape parts processing.

2. High production efficiency: traditional machine tools need multiple clamping, adjustment and other processes to complete the processing of the workpiece, and five-axis linkage machine tools can achieve multiple plane processing through different angles in the case of a clamping, thus greatly shortening the processing time and improving production efficiency.

3. High machining accuracy: The five-axis linkage machining can realize 360-degree rotation and multi-angle tilt machining of the workpiece through the movement of each axis, thus making the machining accuracy higher, especially for the processing of special workpiece, very high machining accuracy can be achieved.

4. High quality of the workpiece: The five-axis linkage machining adopts high-speed tool speed, high-precision tool path control and high-stability machine tool structure, which can ensure the stability and good quality of the surface quality of the machined parts, and improve the quality of the workpiece and the overall processing effect to a certain extent.

5. Easy operation: five-axis linkage machining is generally controlled by numerical control system, the operation is relatively simple, as long as the master of numerical control programming technology, you can easily achieve a variety of complex parts processing, at the same time, the processing process does not require complex equipment and professionals, can reduce operating costs, improve work efficiency.

In short, as a high-end processing technology, five-axis linkage machining has the advantages of wide processing range, high production efficiency, high processing precision, high workpiece quality, easy operation, etc., and will be more and more applied in the future development.

Lianda precision focus on five-axis linkage processing, welcome the need of friends to call for detailed discussion!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers