The five-axis linkage machining center is mostly A “3+2” structure, that is, X,Y,Z three linear motion axes plus A, B, C rotating around the X YZ axis of the two rotation axes. So, in terms of big categories, we have X, Y, Z, A, B; X, Y, Z, A, C; X, Y, Z, B, C three forms. According to the different combination forms of the two rotating axes, there are generally three forms of double rotary table, rotary table with swinging head and double swinging head. These three structural forms, due to physical reasons, respectively determine the size of the five-axis linkage machine and the range of processing objects.

1. Five-axis linkage machine tool with double turntable structure

The table set on the bed can be rotated around the X axis, defined as the A axis, the general operating range of the A axis +30° to 120°. There is no rotary table in the middle of the table rotating around the Z axis, defined as the C axis, the C axis can generally be 360° rotation. In this way, through the combination of the A axis and the C axis, in addition to the bottom surface of the workpiece fixed on the workbench, the remaining five faces can be processed by the vertical spindle. The small index value of the A axis and the C axis is generally 0.001°, which can be subdivided into any Angle to process the inclined plane and the inclined hole. A axis and C axis such as X, Y, Z three linear axis to achieve linkage, you can add a complex space surface, of course, this requires the support of numerical control system, servo system and software. The advantage of this setting is that the structure of the spindle is relatively simple, the rigidity of the spindle is very good, and the manufacturing cost is relatively low. However, the general work table can not be designed too large, the load bearing is small, especially when the A-axis rotation is equal to 90°, the workpiece cutting will bring A large cutting moment to the table.

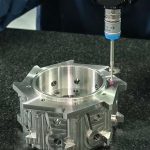

2. Five-axis linkage machine tool with rotating table and swinging head structure

Since the turntable can be A axis, B axis or C axis, the swing head is the same, can be respectively A axis, B axis or C axis, so the turntable plus the swing head structure of the five-axis linkage machine can have a variety of different combinations to adapt to different processing objects. The advantage of this setting is that the spindle machining is very flexible, and the table can also be designed to be very large. The huge fuselage of the passenger plane and the huge engine casing can be machined in this kind of processing. This design has another major advantage: When using a spherical milling cutter to process surfaces, when the center of the tool is perpendicular to the machining surface, because the apex linear speed of the spherical milling cutter is zero, the surface quality of the workpiece cut out by the vertex will be very poor, and the design of the spindle rotation makes the spindle turn an Angle relative to the workpiece, so that the spherical milling cutter avoids the vertex cutting, ensuring a certain linear speed, which can improve the surface processing quality.

This structure is very suitable for mold high-precision surface machining, but it is also difficult to do rotary machining center. In order to achieve high precision of rotation, the rotation shaft is also configured with circular grating scale feedback, and the indexing degree is within a few seconds, of course, the rotation structure of this kind of spindle is more complex, and the manufacturing cost is higher.

3. Five-axis linkage machine tool with double swing head structure

Because of the structure itself, there is generally an electric spindle with a loose broach structure in the middle of the swing head, so the size of the double swing head itself is not easy to make small, generally in 400 to 500mm, plus the need for the range of activity of the double swing head, so the processing range of the five-axis linkage machine tool of the double swing head structure should not be too small, but the larger the better, generally gantry or moving beam gantry, The width of the gantry is better than 2000 to 3000mm.

At present, the more advanced double-swing head type five-axis linkage machine tool swing head structure generally adopts “zero transmission” technology of torque motor “zero transmission” technology in the rotary shaft application is to solve its transmission chain stiffness and accuracy of the ideal technical route. With the development of technology, the manufacturing cost of the twisted motor has been greatly reduced, and the market price has also fallen, and this process will promote the manufacturing technology of the five-axis machine tool to be greatly advanced.

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

您好!Please login