(1) Improve the cutting state and cutting conditions

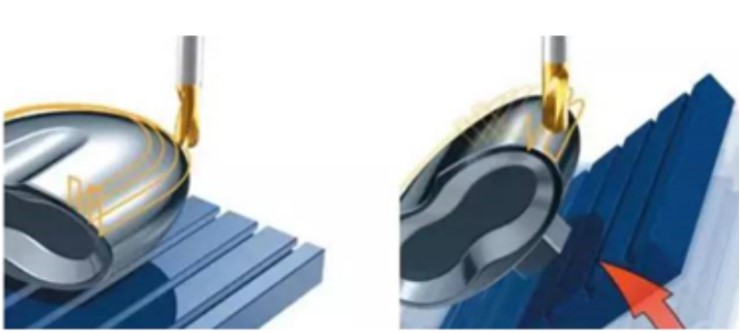

As shown in Figure a), when the cutting tool moves to the top or the edge of the workpiece, the cutting state gradually deteriorates. In order to maintain the optimal cutting state, a rotating table is required. If you want to complete the machining of irregular planes, you also need to rotate the table several times in different directions.

As shown in Figure b) tool tip position diagram, the deflection tool of the five-axis machine tool can avoid the cutting speed of the ball end milling cutter at the center point of 0, and obtain better surface quality.

(2) The production chain and production cycle are shortened

Five-axis CNC machine tool through the spindle head tilt for side wall machining, do not need multiple parts clamping, effectively reduce the positioning error, improve the processing accuracy, and shorten the manufacturing chain. In aerospace, automotive and other fields, with high flexibility, high precision, high integration and complete processing capabilities can well solve the problem of precision and cycle of complex parts processing in the process of new product research and development, greatly shorten the research and development cycle and improve the success rate of new products.

(3) Efficiency improvement and interference elimination

For impeller, blade and mold steep side wall machining, the three-axis CNC machine tool can not meet the processing requirements, the five-axis CNC machine tool can be controlled by the tool shaft space attitude Angle to complete such processing content. At the same time, it can realize short tool processing deep cavity, effectively improve the rigidity of the system, reduce the number of tools, avoid special tools, expand the use of general tools, thus reducing the production cost.

For some inclined surfaces, five-axis CNC machining can use the tool side edge to finish the side wall cutting, so as to improve the machining efficiency and surface quality. The three-axis CNC machining relies on the stratified cutting of the tool and subsequent grinding to approximate the inclination plane.

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

您好!Please login