PBT-PET sheet and bar cnc processing

Machining method: CNC machining

Processing factory: Lianda

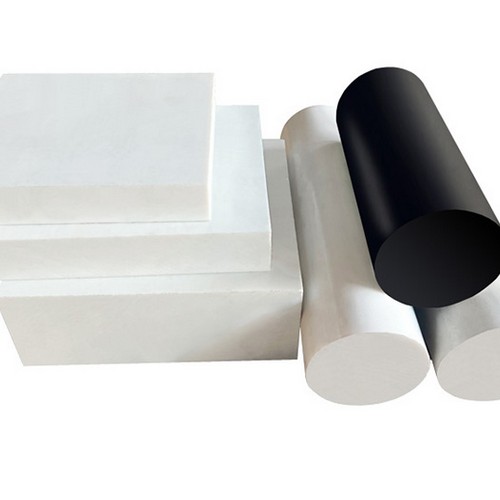

Processing material: PBT-PET sheet bar

Processing equipment: CNC machining machine

Machining method: CNC machining

Processing factory: Lianda

Processing material: PBT-PET sheet bar

Processing equipment: CNC machining machine

Pvt-pet sheet and bar CNC processing

Pvt-pet sheet bar is a common engineering plastic material, often used to make electronic components, automotive parts, mechanical parts and so on. Because of its high hardness, good strength, high temperature stability, more and more attention by the industry and widely used. For this material, we can use CNC machining technology for processing and production.

CNC machining technology is a kind of computer-aided control technology, through the computer program to control the machine tool for automatic processing. It can precisely control the position, speed and Angle of the machining tool, and can achieve high-precision and high-efficiency material processing. In the processing of PBT-PET sheet and bar, CNC processing technology has the following advantages:

1. High precision: CNC machining can precisely control the position and Angle of the machining tool to ensure the accuracy of the processing size and avoid waste and loss caused by manual operation errors.

2. High efficiency: CNC machining can be automatically processed, saving labor and time costs, improving processing efficiency, and significantly improving production efficiency.

3. Good surface quality: CNC machining can achieve high-speed cutting and high-speed precision carving, ensuring the smoothness and smoothness of the processed surface, making the finished surface finish high, good quality, and reducing the cost of subsequent processing and adjustment.

4. Diversity: CNC processing can be a variety of forms, different sizes, different shapes of PBT-PET sheet bars for processing, to produce a variety of different parts, can meet the requirements of different fields.

In short, CNC machining technology is an efficient, high-precision and high-quality processing method, which is of great significance for the processing and production of PBT-PET sheet and bar, and can improve production efficiency and product quality.

Pvt-pet sheet bar is a new kind of high performance material, which has good mechanical properties and chemical resistance, and is widely used in industrial production and daily life. In order to make better use of its properties, it is necessary to CNC machining of PBT-PET sheet bars.

CNC machining is a high-precision, high-efficiency processing technology that can complete the processing of complex shapes in a short time, while ensuring processing accuracy and quality. For the processing of PBT-PET sheet and bar, CNC machining is a very suitable technology.

First of all, the material selection and surface treatment of PBT-PET sheet and bar need to be carried out before processing. PBT-PET sheet bars will be affected by various chemicals and external forces during use, so it is necessary to choose high-quality materials, surface cleaning and treatment before processing, to ensure that there are no scratches, falling off and other situations during processing.

Secondly, it is necessary to choose a suitable CNC machining machine tool according to different processing needs. Pvt-pet sheet bar adopts CNC processing, can be directly three-dimensional processing, high precision, fast efficiency, to meet the needs of complex shape processing. It is necessary to choose the appropriate processing machine tools according to the processing requirements, such as CNC lathes, CNC milling machines, CNC cutting machines, etc.

Next, you need to program and process Settings based on drawings or models. CNC machining needs to write machine tool processing programs and set processing parameters, according to drawings or 3D models to determine the processing path and depth of materials and other parameters, layered, hierarchical programming.

Then, the process needs to be monitored and adjusted. In the processing process, the processing parameters need to be monitored and adjusted to ensure the processing accuracy and quality. Such as deviation, jitter and other problems in the processing process, it is necessary to adjust in time to make the processing process go smoothly.

Finally, the product quality testing and follow-up treatment. After the processing is completed, the quality of the product needs to be tested, such as size, flatness, surface quality, etc. For unqualified products, follow-up treatment is needed, such as re-processing, repair, etc.

In short, the CNC processing of PBT-PET sheet bars needs to go through multiple steps, including material selection, program writing, processing monitoring and product testing, in order to ensure the processing effect and quality. Through reasonable material treatment and CNC processing technology, the efficient processing and wide application of PBT-PET sheet and bar can be realized.

Lianda precision focus on cnc processing, all types of materials can be, welcome to the need of PBT-PET sheet bar cnc processing and five-axis CNC processing friends call consultation details