PP plastic CNC processing

Machining method: CNC machining

Processing factory: Lianda

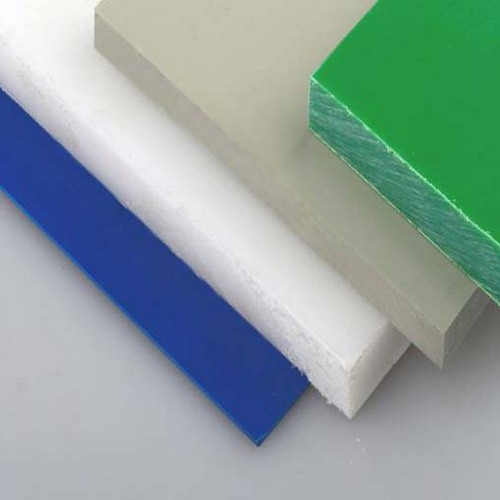

Processing material: PP plastic

Processing equipment: CNC machining machine

Machining method: CNC machining

Processing factory: Lianda

Processing material: PP plastic

Processing equipment: CNC machining machine

PP plastic CNC processing

PP plastic is a common plastic material, which is widely used, such as in medical, electronics, automotive and other fields have important uses. In order to meet the needs of different application fields, PP plastics need to be precision machined. CNC machining is a common machining method, which can achieve high precision machining.

PP plastic CNC machining needs to first select the appropriate processing technology and equipment. First of all, you need to choose the right CNC machine to meet the processing size and accuracy requirements. Secondly, it is necessary to select the appropriate cutting tools and cutting parameters to ensure the cutting quality and speed during the machining process.

When conducting CNC machining of PP plastics, the following points need to be noted:

1. Choose the right processing method: PP plastic has the characteristics of fusible, easy deformation, etc., so it is necessary to choose the appropriate processing method to avoid damage caused by overheating and vibration. Common processing methods include milling, turning, drilling and so on.

2, choose the right cutting tools: PP plastic processing need to choose high-quality, wear-resistant cutting tools to ensure the processing effect. Common cutting tools include end milling cutter, drill, spiral milling cutter, etc.

3. Set the right cutting parameters: The right cutting parameters can ensure the stability and efficiency of the machining process. Cutting parameters include cutting tool speed, feed speed, cutting depth, etc.

4. Fine processing: PP plastic products need to achieve a certain precision, so it is necessary to carry out fine processing, including surface treatment, grinding, etc.

In the process of CNC machining of PP plastics, it is necessary to pay attention to prevent static electricity, avoid excessive vibration, prevent oil pollution, and control the processing temperature. In addition, regular maintenance and repair of the equipment should be carried out to ensure the stability and processing quality of the equipment.

In short, PP plastic CNC machining is a high-precision process, the need to choose the right equipment and cutting tools, set the right cutting parameters, fine processing, pay attention to prevent static electricity, excessive vibration, oil and temperature and other problems to ensure processing quality and production efficiency.

PP plastic is a commonly used engineering plastic, with a series of excellent physical and chemical properties, such as excellent corrosion resistance, heat resistance, wear resistance, electrical insulation, low water absorption and so on. This kind of plastic is widely used in industrial production, especially in mechanical equipment. PP plastic CNC machining is a high-speed, high-precision process that can manufacture a variety of complex components and components, while ensuring product accuracy and performance.

The main process of PP plastic CNC machining includes CAD drawing, CAM programming, engraving and processing. First of all, it is necessary to design the required components and components through CAD software; Secondly, the computer aided manufacturing software CAM is used for programming to convert CAD design graphics into machine-readable G code. Finally, machining and engraving are carried out through a CNC machining center. During the machining process, the table will continuously rotate, the tool will continuously cut the material, according to the pre-set procedure for processing, and finally get the required components and components.

Compared with traditional manual processing, CNC machining of PP plastics has many advantages. First of all, the processing speed is fast, the precision is high, and it can meet the requirements of precision machining. Secondly, due to the high degree of automation, the processing process hardly needs manual intervention, which greatly improves the production efficiency. At the same time, PP plastic CNC machining also has a high degree of repeatability and consistency, which can ensure the accuracy and quality of each part.

PP plastic CNC machining can also carry out a variety of processing, such as turning, milling, drilling, threading, etc., with a wider range of applications. In addition, the process can also be optimized by CAD/CAM software to achieve more efficient processing and further improve production efficiency and production quality.

In short, PP plastic CNC machining is an efficient, high-precision, high-reliability processing method, which is very suitable for the manufacture of various precision components and components. It has significant advantages in reducing labor costs, improving production efficiency and product quality, and is an indispensable part of modern manufacturing.

Lianda precision focus on cnc machining, all types of materials can be, welcome to need PP plastic CNC machining and five-axis CNC machining friends call to consult details