PA plastic CNC machining

Machining method: CNC machining

Processing factory: Lianda

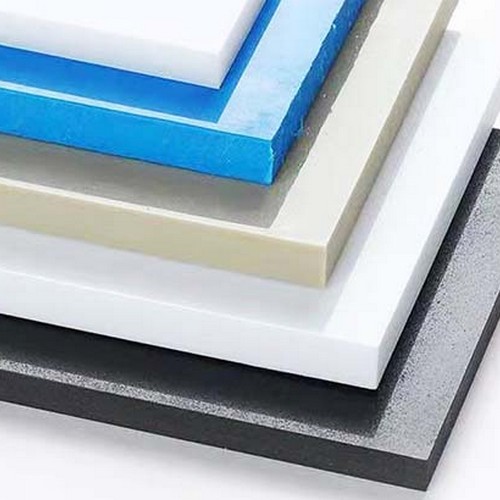

Processing material: PA plastic

Processing equipment: CNC machining machine

Machining method: CNC machining

Processing factory: Lianda

Processing material: PA plastic

Processing equipment: CNC machining machine

PA plastic CNC machining

PA plastic is a high-performance engineering plastic commonly used in the manufacture of mechanical parts, automotive parts, electronics, synthetic fibers and advanced building materials. CNC machining is a common manufacturing method that can be used to make parts and products from a variety of materials. During the machining process, the CNC machine automatically cuts the workpiece through computer control, thus meeting the complex shape and size requirements. In this article, we will discuss CNC machining of PA plastics.

The characteristics of PA plastics

PA plastic has many excellent characteristics, such as high strength, excellent wear resistance, good chemical resistance, low friction coefficient and so on. In addition, it has excellent insulation properties and high temperature resistance, which can be used to manufacture parts that work at high temperatures or pressures. However, PA plastic also has some limitations. For example, it is strongly hygroscopic, with a water absorption rate of around 3%. Therefore, when PA plastics are used to manufacture high-precision or ultra-precision parts, the moisture content before and after processing needs to be considered.

The processing difficulty of PA plastic

Due to the high strength and low coefficient of friction of PA plastic, it will produce high cutting forces and temperatures during processing, which can lead to problems during processing. In order to solve these problems, it is necessary to use the appropriate processing tools and techniques. For example, the number of cutting edges should be appropriately selected in order to reduce the processing temperature and cutting force. In addition, in the processing process also need to use a special cutting liquid cooling workpiece to ensure the surface smoothness and dimensional accuracy of the parts.

CNC machining method of PA plastic

In the CNC machining process, it is necessary to take into account the characteristics and processing difficulty of PA plastic, and implement a reasonable process to ensure the quality of the workpiece. Here are some common CNC processing methods for PA plastics:

1. The use of high-speed cutting tools: the use of high-speed cutting tools can reduce cutting force and temperature. In addition, the use of high-speed cutting tools can also reduce cutting resistance and improve processing efficiency.

2. Select the appropriate processing parameters: In the process of CNC machining PA plastic, parameters need to be selected and adjusted according to the characteristics of the workpiece material, the number of machining cutting edges, cutting fluid, cutting speed and other factors.

3. Treat the material before processing: In order to avoid moisture during processing, PA plastic needs to be dried. In the processing process, it is also necessary to control the temperature and humidity of the room to avoid the instability of the processing quality caused by the moisture absorption of the workpiece.

4. Reasonable selection of cutting fluid: PA plastics need to use special cutting fluid in the processing process to reduce the processing temperature and cutting force to ensure the surface smoothness and dimensional accuracy of the parts.

In short, CNC processing of PA plastics requires deep technical strength and good processing experience. Only through reasonable processing technology and a series of professional skills, can we produce high-precision parts, molds and products that meet the standards.

PA plastic is a kind of high performance material widely used in the field of engineering and electronics, and is also an excellent mechanical processing material. PA plastics have excellent heat resistance, wear resistance and chemical resistance, which can provide higher performance and longer service life. For this material, CNC machining has become one of the common processing methods.

CNC machining is a machining method based on numerical control equipment, which is more accurate and efficient than traditional manual processing and semi-automatic processing. CNC machining machine tools are processed by computer programs to control automatic tools, which can ensure that the size and shape of each product is perfect. Moreover, the versatility and high degree of automation of CNC machining machines make them ideal for machining high-performance materials.

In the CNC machining process of PA plastics, the processing technology and tools must be determined first. PA plastic has good processing properties, but because of its high temperature hardness, it is necessary to use a higher hardness cutting edge to cut. In the cutting process, it is necessary to control the cutting speed and processing depth, so that the heat generated during the processing will not adversely affect the performance of the plastic material.

The next step is to choose the appropriate cutting method. Under normal circumstances, the use of dry cutting is more common, because it can reduce the heat generated during cutting, improve the processing speed and efficiency. However, dry cutting can also easily lead to burrs and residue on the surface of the material. Therefore, it is necessary to control the processing speed and the feed speed of the tool, avoid excessive heat generated during the cutting process, and choose the appropriate lubricant according to the actual situation.

Finally, the finished surface needs to be treated. The surface of PA plastic is smooth, but attention needs to be paid to removing residues and burrs. This can be achieved by means of sandpaper, sander, polisher, etc.

In summary, CNC machining of PA plastic is relatively simple, but it is still necessary to pay attention to some processing details to ensure the quality of the processed products. Using the right tools and processes, reasonable control of heat and speed, cleaning surface residues and burrs, etc., can ensure that the processed products meet the design requirements, with high performance and long life.

Lianda precision focus on cnc machining, all types of materials can be, welcome to need PA plastic CNC machining and five-axis CNC machining friends call for consultation