Optical processing

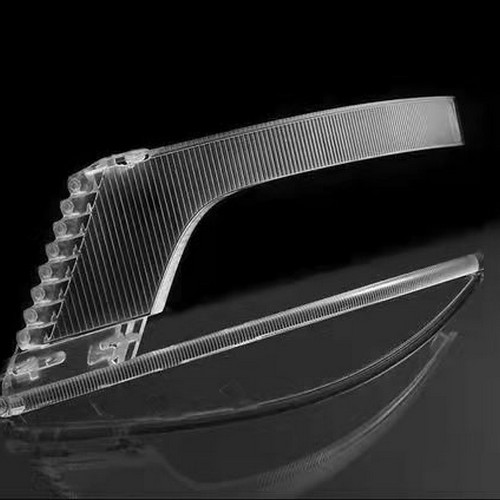

Optical parts processing refers to a variety of fine processing and treatment of optical components to meet the requirements of specific optical properties, so as to be used to manufacture a variety of precision optical instruments and equipment, such as telescopes, microscopes, lasers, measuring instruments, etc. Optical parts processing technology involves optical design, mechanical processing, optical processing, optical detection and other fields, with high precision, high efficiency, high automation and so on.

The primary task of optical parts machining is to make the shape, tolerance, surface accuracy and optical properties of optical components. Shape and tolerance are important indicators to measure the accuracy of optical components, which need to be achieved by machining and precision machining technology. Surface accuracy is the key factor that determines the optical properties of optical components, and it needs to be achieved by optical machining technology. Optical machining includes many technologies such as grinding, polishing, electrolytic polishing, chemical-mechanical polishing and heat treatment. Among them, grinding technology is the most basic and most commonly used technology, which can meet the processing requirements of most optical parts. Polishing technology is a further processing on the basis of grinding, which can improve the surface finish and accuracy of optical components. Electrolytic polishing, chemical-mechanical polishing and heat treatment technologies are developed for the special processing requirements of special optical components.

Optical inspection is an indispensable part of optical parts processing. Optical inspection requires the use of high-precision inspection equipment, such as interferometers, automatic Newton rings, three-dimensional laser scanners. The optical properties of the optical components can be obtained by detecting the surface morphology, phase difference, wavefront distortion and refractive index of the optical components and judging whether they meet the requirements. If the test results do not meet the requirements, the optical performance needs to be improved by reprocessing or adjusting the equipment.

In short, optical processing is a technology that requires high precision, high efficiency and high automation. In the development of modern optical technology, it plays an important role, providing a solid technical guarantee for the manufacture of high-precision and high-performance optical equipment. For the optical parts processing industry, constantly updating technology and improving the processing level is the fundamental to meet market competition.

Optical processing is a high-precision and high-tech processing technology, which is widely used in the manufacture of various optical devices, such as optical instruments, optical information processing equipment, lasers, semiconductor chips and other industries. In the process of optical parts processing, it is necessary to use precision machining and precision measurement technology. Below, we will introduce the optical processing process and its related technologies in detail.

First, the process of optical parts processing

The processing of optical parts is roughly divided into the following steps:

1. Design: First of all, it is necessary to design according to the application requirements of optical components, including optical path design, material type, design parameters, etc.

2. Selection of raw materials: Select suitable materials according to design requirements, such as glass, metal, semiconductor materials, etc.

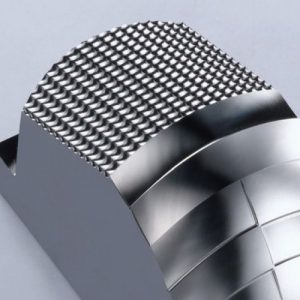

3. Precision machining: The use of traditional machining computer numerical control machining technology to cut, grinding, polishing and other precision processing of raw materials, to achieve the required curvature, surface smoothness, optical quality and other requirements.

4. Optical quality inspection: quality inspection of the processed optical parts, such as precision testing, parallelism, surface quality, etc.

5. Coating treatment: coating or reflection coating treatment of optical parts, and quality testing to ensure the performance and service life of optical devices.

6. Assembly and debugging: Assemble different optical components together, and debug and optimize operations to ensure the accuracy and stability of the optical path.

7. Finished product inspection: Complete inspection of the assembled optical instrument to ensure its performance and quality stability.

2. Related technologies for optical parts processing

1. Precision machining technology

Precision machining is an important technology for optical parts processing, which is a process of processing raw materials through machining, polishing, grinding and other methods to achieve the specified accuracy and surface roughness requirements. Commonly used precision machining processes are machining, polishing, film treatment, chemical etching and so on.

2. Precision measurement technology

Precision measurement is another important technology for optical parts processing, which is the process of detecting the surface roughness, flatness and accuracy of the optical parts after processing. The commonly used precision measurement techniques are: laser interferometer, triangle altimeter, planarity tester and so on.

3. Optical film technology

Optical film technology refers to the technology of depositing thin films on the surface of optical elements to improve their performance such as reflection, transmission or spectroscopy. The commonly used optical film technologies include electron beam evaporation, magnetron sputtering, ion beam deposition, etc.

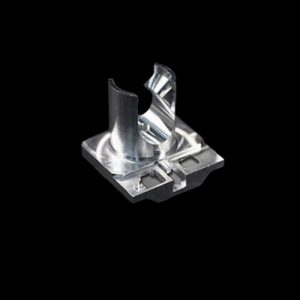

4. Automatic processing technology

With the rapid development of automation technology, automatic processing technology has been widely used in the field of optical parts processing. Automated processing can improve production efficiency and accuracy, and reduce the waste of manpower and materials, saving production costs. Common automated processing technologies include CNC machine tools, robot processing, laser processing and so on.

In short, optical parts processing is a difficult, high-precision, high-technology processing technology. In the processing process, it is necessary to use advanced precision machining and testing technology, especially the application of automated processing technology to improve production efficiency and quality stability.

Dongguan Lianda focus on optical parts processing, five-axis linkage processing, welcome the need of friends to call for detailed discussion!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers