Multi-axis precision machining

Multi-axis precision machining is an important machining technology in modern industry, which is widely used in aviation, automobile, medical equipment and other fields. Multi-axis machining refers to the use of CNC machine tools and other equipment for processing, while controlling the action of multiple axes, in order to achieve high-precision machining of the shape and size of the workpiece. In general, modern CNC machining equipment can achieve five-axis, six-axis, seven-axis and even higher axial processing, with high efficiency and high precision.

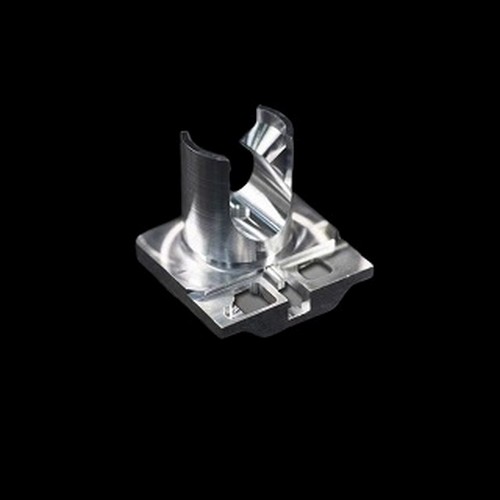

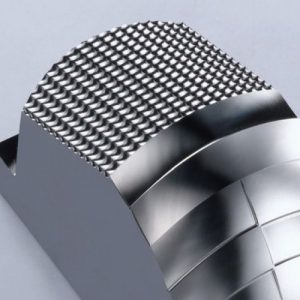

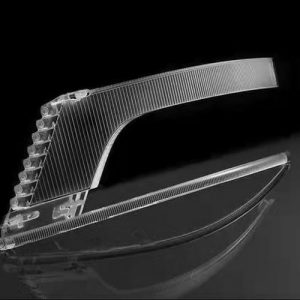

Multi-axis machining is mainly used to deal with parts with complex shapes and curved surfaces, such as curved cutting knives, spiral gears, threaded cams, etc. It uses advanced numerical control technology to control the axial movement, rotation, tilt and other actions of the tool, so that the machining tool can be cut or formed along any curved surface trajectory, so as to achieve the manufacturing of difficult workpieces.

The advantages of multi-axis machining are high precision, high efficiency and wide processing range, which can meet the requirements of different industries for the shape and size of the workpiece. In the field of aerospace, multi-axis machining is an important means to achieve high-precision parts processing, such as turbine blades, engine cabin doors, wings and other complex parts processing are inseparable from the support of multi-axis machining technology. In automobile manufacturing, multi-axis machining is widely used in engine cylinder block, crankshaft, gear box and other parts manufacturing. In the field of medical equipment, multi-axis machining is used to manufacture prosthetics, artificial joints, implants and other parts that require high precision machining.

In general, multi-axis precision machining is one of the key technologies of modern industry, which plays a significant role in improving workpiece processing accuracy, improving equipment manufacturing efficiency, and promoting industrial technological progress and industrial upgrading. With the continuous emergence of new processes, new materials and new technologies, multi-axis machining will continue to play an important role in achieving efficient precision machining and improving quality levels, contributing more outstanding results.

Multi-axis precision machining is a kind of advanced CNC machine tool machining method, which can simultaneously handle the stepping motion in multiple directions. It is implemented with multiple motors and controllers, enabling precise cutting of workpieces in space. In the field of industrial manufacturing, multi-axis precision machining is often used to produce high-precision parts and components, such as turbine blades and steering gear in the aerospace field, medical devices and artificial joints in medical equipment.

The advantages of multi-axis precision machining technology are high precision, high efficiency and flexibility. By using multiple motors and controllers, it can master position, speed and acceleration in multiple directions at the same time. This allows multi-axis machines to cut complex shapes and curves faster than single-axis machines. In some applications, multi-axis machines can hold multiple tools at the same time, each cutting at a different Angle, allowing for multiple operations at the same time, increasing production efficiency. In addition, the multi-axis machine can also automatically adjust the position of tools and workpieces, saving the time and cost of user adjustment.

In multi-axis machine tools, people usually use the spindle and auxiliary shaft accessories. The main shaft is the main shaft for making the workpiece, and the auxiliary shaft is usually used for auxiliary processing, such as processing with different angles of the drill or grinding head on the same workpiece. Multi-axis machine tools are usually subjected to great mechanical pressure, so the design must have a high degree of stability and stiffness.

Multi-axis precision machining has many applications, most notably in aerospace and medical device manufacturing. In the aerospace sector, multi-axis machine tools can be used to produce turbine engines, cutting the time required for various smaller parts inside the engine. In the field of medical devices, multi-axis machine tools can be used to manufacture artificial joints, such as artificial hip joints and artificial knee joints. These parts require high precision because they need to work with the joints of the human body to treat difficult diseases.

In short, the development of multi-axis precision machining technology is crucial to the development of manufacturing. It can improve the precision and efficiency of the manufacturing process, while making production more flexible and sustainable. In the future, with the further development of technology, multi-axis precision machining technology will continue to promote the development of manufacturing.

Dongguan Lianda focus on multi-axis precision machining, five-axis CNC machining for many years, rich experience, welcome the need of friends to call for detailed discussion!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers