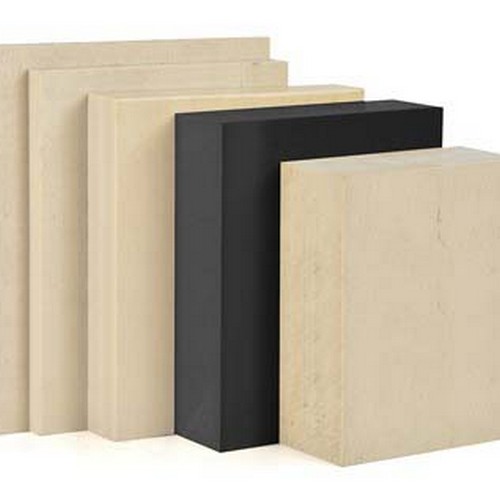

PEEK material CNC machining

Machining method: CNC machining

Processing factory: Lianda

Processing material: PEEK material

Processing equipment: CNC machining machine

Machining method: CNC machining

Processing factory: Lianda

Processing material: PEEK material

Processing equipment: CNC machining machine

PEEK material CNC machining

PEEK material is a kind of high performance engineering plastic, with excellent mechanical properties, chemical stability and high temperature resistance. Therefore, it is widely used in many industries requiring high performance, such as aerospace, medical equipment and other fields. The use of CNC machining PEEK materials is a very effective way.

First of all, a brief introduction to PEEK materials. PEEK is the abbreviation of polyether imide, this material can maintain stability at high temperatures, with heat resistance, wear resistance, chemical corrosion resistance and a series of advantages. In the field of mechanical applications, the most widely used is PEEK nylon, which is more concentrated and stronger than PEEK, but the price is higher than materials such as PEK and PTFE.

CNC machining technology is often used to make precision parts because it has the characteristics of high efficiency and precision. The use of CNC machining PEEK materials can optimize the production process more than the traditional production method. It allows for more precise processing and better control over size, shape and finish requirements, especially when working with high-performance materials such as PEEK.

How to do that? First of all, the mechanical properties of PEEK material are very strong, but its processing is also very difficult. PEEK material has very strict requirements for the selection of cutting tools and the selection of parameters for CNC machining. Under normal circumstances, it is best to choose a tool with a relatively low heat PVD coated tungsten steel, which can reduce the melting point and viscosity of PEEK, cutting efficiently and without too much thermal damage to the material.

Secondly, the appropriate CNC machining parameters can also ensure the machining quality. When performing PEEK CNC machining, it is best to control the speed at a low speed, and the processing speed is not too fast, which can not only reduce the error, but also effectively prevent the material from breaking and other situations. The most important thing is that a high-level technical team is needed to solve problems in the production process at any time to ensure production efficiency and product quality.

In general, the high performance of PEEK materials and the high efficiency of CNC machining technology are a very good choice for making high-precision parts in many industrial fields. In order to achieve good results, you need to choose the right cutting tools and parameters, while having a high level of technical personnel to ensure that the production process is correct.

PEEK material is a kind of high performance engineering plastic with high temperature, chemical corrosion resistance and excellent mechanical properties, widely used in automotive, aerospace, medical, electronics and other fields. In the processing of PEEK materials, CNC machining is a common method. This paper will introduce the specific process and precautions of PEEK material CNC machining.

First, PEEK material CNC machining process

1. Design CAD model

First, designers need to create 3D models of PEEK parts using CAD software.

2. Write CAM program

Next, it is necessary to use CAM software to complete the processing program of PEEK parts, including the cutting tool path, tool parameters, cutting depth and other parameters. It is necessary to decide which cutting tool to use according to the shape and requirements of different PEEK parts, as well as different parameter Settings.

Step 3 Pretreat

Prior to the start of machining, the PEEK material needs to be pre-treated to ensure that the required accuracy and surface quality can be achieved during CNC machining. Pretreatment can include cleaning, removal of material defects, heat treatment, etc.

4.CNC machining

Before CNC machining, the following preparations need to be made. First, you need to select a suitable CNC machining machine, and then install the cutting tools and fixtures to be used. Next, the program needs to be loaded into the machine and processed. CNC machining can be carried out by multi-axis machining centers or by large lathes.

5. Finishing and smoothing

After the completion of the primary machining, the PEEK material needs to be finished and smoothed to achieve the desired surface quality and precision. Finishing includes processes such as sliding cutting and grinding, while smoothing can be selected by sandblasting or polishing.

6. Check and test

After processing, inspection and testing are required to ensure that the PEEK material parts meet the design requirements. Inspection and testing may include the use of a microscope to check surface quality, solder joint quality, dimensional accuracy, and mechanical strength testing and chemical test analysis.

Second, PEEK material CNC processing precautions

1. Use the right tools

PEEK material has high hardness and temperature resistance, so it is necessary to choose cutting tools with sufficient hardness and wear resistance. Under normal circumstances, tungsten carbide tool is the best choice.

2. Stable processing temperature

When the PEEK material encounters too high airflow or too long machine operation time, it will cause the temperature to rise, thus affecting the processing effect. Therefore, it is necessary to maintain temperature stability and process in an appropriate temperature range.

3. Adjust the processing speed

Compared with ABS, PC and other materials, the processing speed of PEEK materials is slow. In CNC machining, it is necessary to set the appropriate cutting speed to ensure that the PEEK material is not excessively damaged by heat, as well as to achieve the required surface quality and accuracy.

4. Follow the correct processing sequence

Different PEEK parts require different processing sequences. In general, the inner cavity should be machined first, and then the outer shape and details should be machined later. This can avoid trying to process in too small a space, thus affecting the processing efficiency and quality.

In short, PEEK material CNC machining is a very high skill and words, proficient in the specification of the operation program, the need to choose the appropriate tools and fixtures, and follow the required processing sequence to ensure that the finished parts can meet the requirements of customers.

Lianda precision focus on cnc machining, all types of materials can be, welcome to need PEEK material CNC machining and five-axis CNC machining friends call to consult details