Optical parts processing

Optical components are a class of key components used in the assembly and manufacture of optoelectronic devices. The manufacturing process of these optical components requires high-precision processes and high-precision machining equipment. In the application of modern optoelectronic technology, optical components are widely used, including communication fiber, optical sensor, optical instrument, semiconductor process and so on. Optical parts processing plays a crucial role in the high performance, quality and reliability of various optoelectronic equipment.

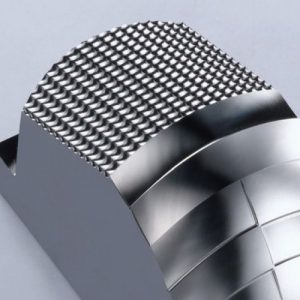

First of all, optical parts processing requires high-precision technology. The fabrication of optical components requires extremely high precision, and typically the spot diameter of the beam can be as small as 1 micron. Therefore, the processing requirements of optical parts are very high, involving mechanical processing, electrochemical processing, optical processing, coating and etching processes. Optical components must be carefully machined to meet the special properties and design requirements of the material.

Secondly, optical parts processing requires high-precision processing equipment. At present, the high-precision processing equipment used for processing optical parts mainly includes CNC machining equipment, electrochemical processing equipment, laser processing equipment, ion beam processing equipment and so on. These devices have the characteristics of high precision and high stability in the processing of optical parts, and can meet the requirements of accuracy, surface quality, size and shape. Therefore, when manufacturing optical parts, in order to obtain high-quality products, it is necessary to use high-precision processing equipment.

Finally, optical parts processing requires professional skills and experience. Machining precision optical parts requires operators to be proficient in processing operations, familiar with the design requirements and processing technology of parts, and have rich processing experience. In actual operation, the adjustment of processing parameters and the maintenance of equipment need to be strictly mastered. Especially in the details of surface treatment, cleaning, transmission and other aspects of the processing process, it is necessary to strictly follow the operating specifications to ensure the processing accuracy and surface quality of the optical parts.

In summary, the manufacture of optical components is of great significance to the technological development of modern optoelectronic equipment. Optical parts processing requires high-precision technology, high-precision processing equipment and professional skills and experience. In the manufacturing process, the need for scientific and reasonable processing technology and strategy, flexible processing programs and management models to meet the evolving market demand and technical requirements.

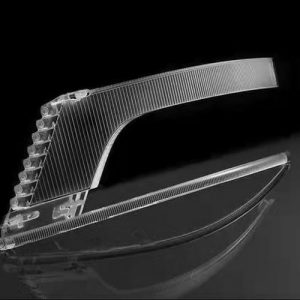

Optical parts are high-precision parts that are widely used in various optical devices, such as telescopes, microscopes, cameras, lasers, and so on. The accuracy of optical parts directly determines the use effect and accuracy of optical equipment, so the processing process of optical parts needs to go through a series of high-precision processing technology.

The processing technology of optical parts involves multi-disciplinary knowledge, such as optics, mechanics, physics, etc. The key to the processing of optical parts is to ensure the smoothness and accuracy of the optical surface, which requires that the processing error and surface quality must be strictly controlled during the processing.

The processing of optical parts usually includes the following steps:

1. Preparation of optical parts before processing: including checking drawings, checking raw materials, confirming processes and preparing processing equipment.

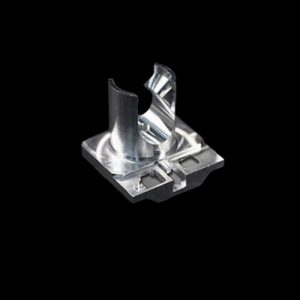

2. Roughing: Roughing refers to the process of removing excess material on the surface of the material, and the commonly used processes are turning, milling, cutting and grinding.

3. Finishing: After roughing, precision machining is needed to achieve higher accuracy and surface quality. Common processes include grinding, polishing and EDM.

4. Inspection: Inspection is required after processing to ensure the use effect and accuracy of optical equipment.

In the processing of optical parts, the precision requirements are very high, especially the control requirements for surface roughness are also very high. Therefore, it is necessary to measure the workpiece accurately and determine its geometric parameters and surface characteristics before machining. In the processing process, it is necessary to strictly control the processing error and surface quality, and check, correct and remedy in time to ensure the processing effect and processing accuracy.

In short, the optical processing process requires strict control of processing errors and surface quality, and requires high-precision processing technology and professional detection means, which puts high requirements on the technical level and equipment requirements of the processor.

Dongguan Lianda engaged in optical parts processing for many years, has a wealth of experience and excellent team, welcome the need for optical parts processing and five-axis processing friends call consultation details!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers