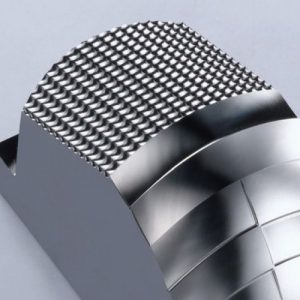

Five-axis machining of rotary disk is a new type of metal processing technology, and it is also an efficient and high-precision machining method. It is modified on the traditional machine tool, the use of multiple axes to achieve multi-direction processing, to meet the processing needs of a variety of complex shapes, with high accuracy and efficiency, is widely used in aviation, aerospace, automotive, electronics and other industries in the manufacturing process.

Compared with the traditional CNC milling machine, the rotary five-axis machining has higher machining efficiency and higher precision. Because it uses multiple axes to achieve rotation and tilt, it can meet the processing needs of various complex shapes during the processing process, and can also complete multiple surface processing at one time, improving processing efficiency and reducing processing costs to a certain extent.

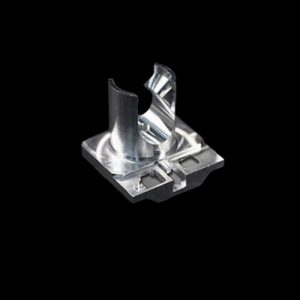

The main equipment of five-axis machining of rotary table includes CNC milling machine, five-axis fixture of rotary table, tool library, cutting fluid system, etc. Among them, the five-axis fixture is one of the key equipment, which can ensure the fixed and stability of the workpiece, so as to ensure the processing accuracy. The tool library can store a variety of different types of tools to cope with the processing needs of different shapes. The cutting fluid system can provide cooling and lubrication functions to ensure the smooth process, while also reducing tool wear and extending the service life.

In the process of rotating disk five-axis machining, paying attention to the following aspects will help improve processing efficiency and accuracy:

1. Choose the right fixture: Choose the right fixture according to the shape and material characteristics of the workpiece to ensure that the workpiece remains stable and in the correct position during processing.

2. Reasonable choice of tool: Select the right tool in the tool library, according to the shape and material characteristics of the workpiece, as well as the cutting force and temperature in the process of machining, develop a reasonable tool selection scheme.

3. Control cutting speed and feed rate: according to the material and shape of the workpiece, reasonable control of cutting speed and feed rate to ensure the stability and processing accuracy of the tool during processing.

4. Establish a reasonable processing strategy: formulate a reasonable processing strategy for different shapes of the workpiece, adjust and optimize the strategy according to the problems in the processing process, and improve the processing efficiency and accuracy.

In summary, rotary five-axis machining is an efficient and high-precision machine machining method, which is suitable for metal processing needs of various shapes and is widely used in the manufacturing process of aviation, aerospace, automotive, electronics and other industries. In the processing process, it is necessary to pay attention to the selection and control of fixtures, tools, cutting speed and other factors, and at the same time, it is necessary to establish a reasonable processing strategy in order to better play the advantages of five-axis machining of the rotary table.

Rotary five-axis machining is an efficient machining method that can precision machining a variety of hard materials, such as metals, ceramics and plastics. Turntable five-axis machining technology is to clamp the workpiece on the turntable, and realize the machining of the workpiece at various angles through the five-axis machining center, making the processing more efficient, accurate and stable.

The characteristics of five-axis processing of turntable:

1. The multi-sided processing of the workpiece can be completed on a fixture, which greatly improves the production efficiency.

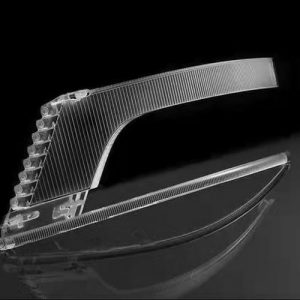

2. Through the cutting function of the five-axis machining center, easy precision machining can be achieved at the bottom of the part or in hard-to-reach areas.

3. High machining accuracy, can ensure the dimensional accuracy and surface quality of the workpiece, to meet the needs of high-precision machining.

4. Different tools can be used in turn to achieve the flexibility of processing.

Scope of application of turntable five-axis machining:

1. Metal processing: suitable for titanium alloy, stainless steel, aluminum alloy and other metal materials processing and parts manufacturing.

2. Hard material processing: suitable for ceramics, glass, stone and other hard materials precision processing and parts manufacturing.

3. Large parts manufacturing: Rotary five-axis machining can quickly and accurately process large mechanical parts to improve production efficiency and quality.

In short, rotary five-axis machining technology is an efficient and accurate processing method, suitable for manufacturing high-precision, small batch, complex shape of the workpiece, is an indispensable part of modern manufacturing.

If you need five-axis CNC machining, welcome to inquire and discuss!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers