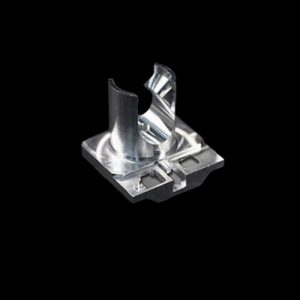

Five-axis machining is a technology of machining parts using CNC machine tools. Compared with the traditional process, it has higher machining accuracy, shorter processing time and better surface quality. It is often used to process complex shaped parts, such as aircraft engine impellers and turbines.

Five-axis machining is a multi-axis machining technology, which can complete the processing of different parts of a workpiece in the same machining. The implementation of this technology requires the use of a five-axis CNC machine tool, which can change the direction and position of the tool during the machining process, so that complex shapes can be completed.

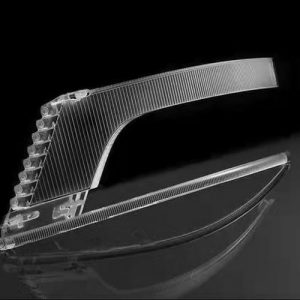

In five-axis machining, the machining path of the workpiece is generated by a 3D model in CAD software. The CAM software then generates a machining program according to this trajectory and transmits the required machining information to the CNC machine tool. CNC machine tools use this program to control the movement and position of the tool to complete the processing of the workpiece.

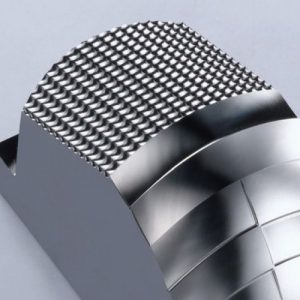

Because more cutting directions and angles can be achieved with five-axis machining, a greater variety of operations can be completed in a single machining. This makes the five-axis machining more efficient and accurate than the traditional step-by-step machining. In addition, five-axis machining can create a very fine bump texture on the surface of the workpiece, which is impossible to achieve with traditional machining methods.

The application range of five-axis machining is wide, mainly used in aviation, automobile, medical equipment and other industries. Taking the application in the aviation industry as an example, complex parts such as turbines and impellers in aircraft engines need to be produced through five-axis machining. These parts require very high machining accuracy, and the five-axis machining is the best choice to meet these requirements.

In short, five-axis machining is an efficient and accurate processing technology, which has great application prospects in industrial production.

Biting is a common five-axis machining method, also known as "biting edge machining" or "cutting machining", it is a difficult CNC machining technology carried out on a five-axis CNC machine tool. This technology usually combines numerical control machining with physical machining, and the processing tool used is a flower biting knife. The teeth of the flower cutter are very hard and can quickly cut the substrate and mark a honeycomb pattern on its surface. This processing method is widely used in the manufacture of high-strength alloy materials, which is suitable for aerospace, automobile manufacturing, construction and other fields.

One of the advantages of bite processing is that it can reduce processing defects and improve conformity and integrity. By biting the workpiece, it can produce a pattern similar to the grid on its surface, increase the contact area of the workpiece, and improve the surface hardness and strength. Over a long period of use, these bite marks will gradually improve the surface condition of the workpiece and give full play to its strength and wear resistance.

The difficulty of the bite processing mainly lies in the high precision requirements of the CNC machining machine. If you can not cut the required geometry in a very short time or can not correctly calculate the relative position of the machining tool and the workpiece, it will lead to processing failure. At the same time, because the bite machining involves complex machining forms such as 3D surface cutting, accurate CAD design and CAM machining programs are needed to support this highly complex machining method.

Because the teeth of the bite knife are very hard, and the workpiece material is mostly high-hardness alloy material, the choice of cutting fluid also needs to be taken into account during the bite processing. Under normal circumstances, the use of tungsten carbide cutting knife requires the use of high pressure cooler for cutting fluid injection to ensure that the cutting fluid completely covers the cutting tool and the workpiece surface, while keeping the cutting fluid in the process of cooling and lubrication to improve the efficiency and accuracy of processing.

To sum up, flower biting is a very difficult five-axis machining technology, but it has a wide range of application prospects in aerospace, automobile manufacturing and other fields. With the progress of technology, more and more enterprises will pay attention to the development and application of biting flower processing technology, and continuously improve the technological level and processing quality of biting flower processing through technological innovation and mechanical improvement, and contribute to the development of manufacturing industry.

Dongguan Lianda specializes in five-axis processing of biting flowers, welcome friends who need to call for detailed discussion!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers