Surface multi-surface machining is an important machining method in modern machining industry, especially for these complex curved parts. Curved surface machining is a highly controllable, high precision and high efficiency machining method, which can greatly improve the accuracy and surface quality of the workpiece. This paper will introduce the principle, method and related equipment of surface multi-surface machining.

Surface multi-surface processing principle

Surface multi-surface machining is a way of machining on different planes by using a tool. Surface multi-surface machining requires a complete and accurate 3D digital model of the workpiece surface, which is designed and drawn by 3D software.

In the process of surface multi-surface machining, the workpiece is first clamped to the processing platform, and the tool is moved according to the designed trajectory, and the cutting is carried out on different planes. Because the cutting is carried out on different planes, a wide cutting area can be obtained, thus speeding up the processing of parts. In the entire machining process, it is necessary to control the cutting depth and cutting speed of the tool to ensure that the machined parts meet the design requirements.

Method of surface multi-surface machining

There are three main types of surface machining methods: machine tool secondary positioning method, machine tool tertiary positioning method and five-axis linkage method.

Second positioning method of machine tool

The machine tool secondary positioning method is one of the most common curved surface machining methods, which is characterized by rotating the machine tool bed at a certain Angle and cutting the tool after rotation. This processing method requires the use of special fixtures to ensure that the position of the parts is unchanged, and can be processed multiple times on a plane, and the whole process of processing can be completed by constantly rotating the workpiece.

Three times positioning method of machine tool

The three times positioning method of machine tool is a method of machining by using the extreme movement of machine tool. In this machining method, the workpiece can be translated and rotated at the same time, and can remain parallel to the specific position of the bed, so as to achieve cutting in three-dimensional space. This method can accelerate the machining speed and maintain high machining accuracy.

Five axis linkage method

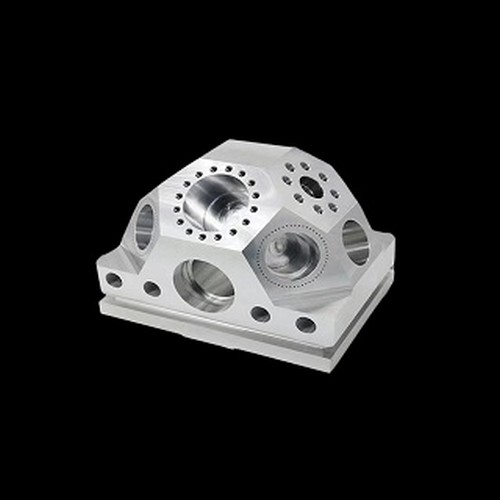

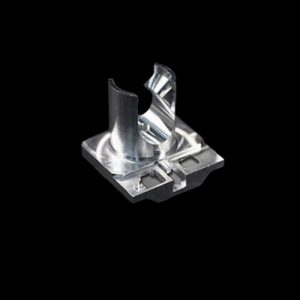

The five-axis linkage method is also one of the common methods for surface machining. This machining method uses a five-axis linkage to determine the Angle and position of the tool, which can complete more cuts in the same machining time and maintain high machining accuracy. Especially for complex 3D surface machining, the five-axis linkage method can be used to achieve better machining.

Curved surface multi-surface processing equipment

Surface machining is usually done using CNC machine tools and CNC machining centers. These machines have a high degree of automation and can be numerically controlled to complete the processing of complex parts. In addition, it also requires appropriate fixtures, tools, appropriate materials and other supporting equipment, as well as 3D model software.

Surface multi-surface machining is an important machining method, which can produce complex surface parts with high precision, high efficiency and good repeatability. With the continuous progress of science and technology, curved surface multi-surface processing technology will be more and more mature, can better meet the needs of the processing industry, become an important production tool in the future market competition to stand out.

Surface multi-surface machining is an effective way of machining on complex surface and machining interface. It includes tool path planning, cutting force control, machine tool precision control and other technologies, which can carry out efficient, high-precision and high-quality machining on various materials.

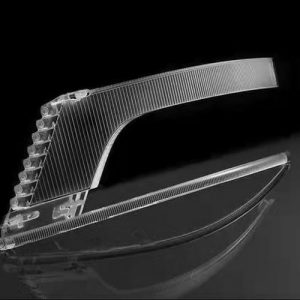

The application of surface multi-surface machining technology has a wide range of application prospects, especially in aviation, automobile, mold and other industrial fields, is widely used. In the process of machining, the surface multi-surface machining technology can solve the bending, stretching, deformation and other problems caused by mechanical mechanics and material factors. At the same time, the technology can also improve material utilization and processing efficiency through processing data optimization.

In the development direction of surface multi-surface processing, there are the following aspects worthy of attention:

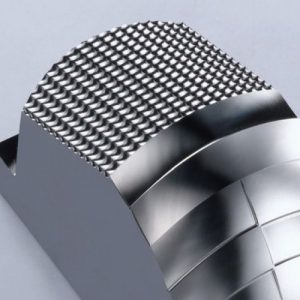

1. Multiple types of surface cutting technology: With the development of surface multi-surface processing technology, various new cutting technologies continue to emerge, such as equal diameter tools, multi-edge tools, wire cutting technology, etc.

2. Precision control technology: precision control technology is one of the keys of surface multi-surface machining technology. The precision control, tool stiffness and machining force control of machine tools are very important technical means, and the improvement of these technologies will further improve the processing quality and efficiency.

3. New material processing technology: curved surface processing technology is widely used in aviation, automotive and other industrial fields. With the progress of new materials, the technology of surface multi-surface machining is also facing new challenges. Therefore, it is necessary to develop new processing technology to meet the processing needs of new materials, and at the same time make curved surface multi-surface processing technology have better performance in the field of new materials.

Because the superior nature of curved surface machining technology has been widely recognized, many machining manufacturers are vigorously promoting this technology. However, the further development of this technology also requires a comprehensive grasp of various technologies and continuous innovation. It is believed that through the continuous research and development of surface multi-surface processing technology, it will become more and more important technology in the machining industry.

Dongguan Lianda professional engaged in surface five-axis processing for many years, welcome the need of friends to inquire detailed talk!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers