Surface machining is a manufacturing process used to manufacture curved surfaces and curved parts of various complex shapes. Surface machining technology is a multi-disciplinary technology, which needs to cover the knowledge of machinery, engineering, materials and other fields. It is widely used in various industrial fields, including automobiles, aviation, medical devices, ships, electronics, stage art and so on.

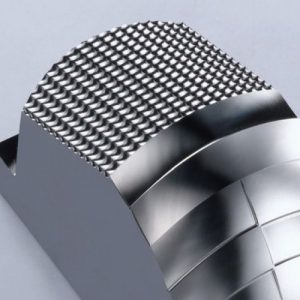

There are many kinds of process methods for surface processing, including numerical control processing, manual processing, sheet metal processing, casting processing and so on. Among them, CNC machining is the most common way of surface machining, which combines computer technology and mechanical manufacturing, and can realize the fine machining of surface quickly and with high precision. The basic principle of CNC machining is to convert the curve image into machine instructions through the computer program, and then control the movement trajectory of the machine tool to carry out machining.

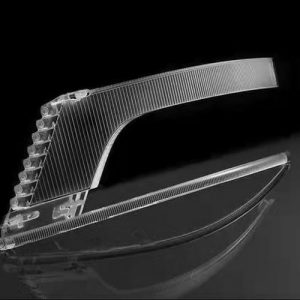

Surface processing materials are also very diverse, including a variety of metals, non-metals, plastics, rubber, composite materials and so on. Different materials require different processing processes and machine tools to meet the requirements of processing quality, efficiency and cost.

Surface processing has important applications in industrial manufacturing, such as in the automotive field, surface processing can be used to manufacture body metal, wheels, engine parts and so on; In the field of aerospace, surface machining can be used to manufacture aircraft aerodynamic shape, fuselage parts and so on; In the field of medical devices, surface machining can be used to manufacture prosthetic limbs, dental instruments and so on.

In addition, surface processing is also widely used in the field of stage art. Surface processing technology can produce a variety of strange stage forms, so that the audience can get more wonderful visual enjoyment.

In short, surface processing, as a basic process, has been deeply involved in various fields of production and manufacturing, and has gradually become an indispensable technology in modern industry and manufacturing.

Surface processing is a manufacturing process that uses machine tools to process surfaces with complex graphics to make them meet engineering requirements. Different from the traditional plane processing, surface processing because of its greater processing difficulty, the need for higher precision equipment and technology, so the development of surface processing technology has been an important direction of the development of manufacturing industry.

The main methods of surface machining include: milling, turning, EDM, polishing and spraying. Among them, milling and turning are the most common methods, milling is suitable for larger volume and relatively flat surface processing, and turning is suitable for small and high-precision surface processing.

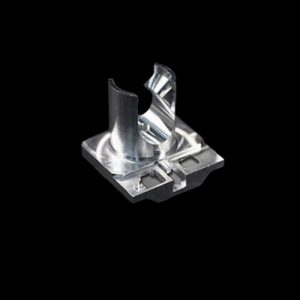

The main application areas of surface processing are aerospace, automobile manufacturing, mold manufacturing, medical equipment and so on. In the field of aerospace industry, surface processing technology is widely used, such as aircraft fuselage, engine blades, etc., need to use surface processing technology; In the field of automobile manufacturing, surface processing technology can be used to manufacture automobile body, engine parts, etc. In the field of mold manufacturing, surface processing technology is widely used in the manufacture of plastic molds, die casting molds and other parts; In the field of medical devices, surface processing technology can be applied to the manufacture of artificial joints and dental orthotics.

With the continuous development of technology, surface processing technology has also been continuously improved and improved, mainly in the following aspects:

The first is the improvement of processing accuracy. With the development of numerical control technology, the precision of surface processing equipment has been improved, and various complex workpieces can be processed more accurately.

The second is the improvement of processing efficiency. With the upgrading of mechanical equipment and control systems, the speed of surface processing has been greatly improved, and the production efficiency has been correspondingly improved.

The second is the expansion of processing materials. Surface processing is no longer limited to the processing of metal materials, but also can be processed non-metallic materials, such as plastics, ceramics and composite materials.

Finally, the degree of automation and intelligence is improved. With the application of artificial intelligence technology, surface processing technology has realized digitalization and intelligence, improved production efficiency and reduced production costs.

To sum up, surface processing technology has become one of the indispensable and important technologies in modern manufacturing industry, and with the continuous development of technology, it will also play its huge role in a wider range of fields.

Dongguan Lianda professional engaged in surface five-axis processing for many years, welcome the need of friends to inquire detailed talk!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers