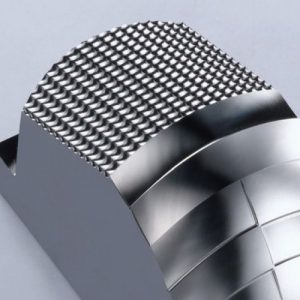

Surface five-axis machining is a high-precision machining method that can be used to manufacture parts with complex surface shapes. Surface five-axis machining achieves a higher level of precision and higher quality machining by rotating the workpiece and tool at multiple angles while also moving the XYZ three-way.

The use of surface five-axis machining is very wide and can be used to manufacture parts and products in various industrial and artistic fields such as aerospace, automotive, medical devices, dentures and artwork. In addition, surface five-axis machining is also widely used in mold manufacturing, because it can process molds with complex surface shapes.

The biggest advantage of surface five-axis machining compared with traditional three-axis machining is the ability to complete multiple angles of cutting on the same machine tool, which reduces the need to transfer the workpiece between different machines or workstations, and also reduces machining errors. Because the tool Angle can be adjusted during machining, it can also be better adapted to different shapes and materials of the workpiece.

The use of surface five-axis machining requires high-precision machine tools and machining tools, as well as precise process control. Surface five-axis machining needs to consider many factors, such as tool radius, Angle and Angle change, machining surface inclination Angle, trajectory and path planning.

Compared with traditional machining methods, the cost of surface five-axis machining is higher, because the equipment such as machine tools and tools is higher, and it requires workers with a high skill level to operate and manage. However, because surface five-axis machining can process complex, high-precision parts and products, so that it has high added value, it is still widely used.

In short, surface five-axis machining is a high-precision, high-quality machining method suitable for manufacturing parts and products with complex surface shapes. It requires high-precision machine tools, tool and process control, highly skilled worker operation and high cost input, but can provide high added value for products, so it is widely used in various industrial and artistic fields.

Surface five-axis machining is a high-end CNC machining technology, which can realize the high-precision machining of complex surface parts. Compared with the traditional three-axis machining, the surface five-axis machining can be processed in more directions, so as to achieve higher processing accuracy and processing efficiency.

Advantages of surface five-axis machining:

1. Can handle more complex surface shapes. When carrying out three-axis machining, it can only be processed along the x, y and z axes, while in surface five-axis machining, it can also be processed on the surface of the workpiece, so that more complex surface shapes can be processed.

2. Higher machining accuracy can be achieved. Because the surface five-axis machining can be processed in more directions, the cutting tool can be better close to the workpiece, thus achieving higher processing accuracy.

3. Higher processing efficiency can be achieved. Compared with the traditional three-axis machining, the surface five-axis machining can complete the machining task faster, which can improve the production efficiency and reduce the production cost.

Application fields of surface five-axis machining:

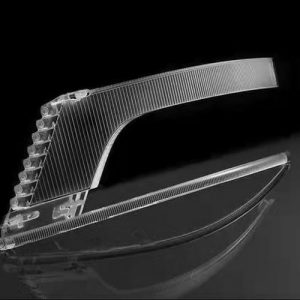

1. Aerospace. Curved five-axis machining can be used to manufacture high-precision parts such as aeroengine impellers and complex turbine blades.

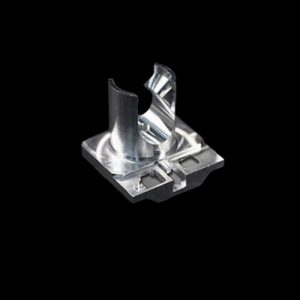

2. Mold manufacturing. Surface five-axis machining can be used to manufacture complex molds, such as automotive sheet metal molds, plastic products molds, etc., which can improve the processing accuracy and processing efficiency of the molds.

3. Medical device manufacturing. Curved surface five-axis machining can be used to manufacture various complex parts in medical devices, such as artificial joints, dental repair equipment, etc.

In short, surface five-axis machining is a high precision and high efficiency NC machining technology, which has a wide application prospect. In the future, surface five-axis machining will gradually replace the traditional three-axis machining and become one of the mainstream technologies of CNC machining.

Dongguan Lianda professional engaged in surface five-axis processing for many years, welcome the need of friends to inquire detailed talk!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers