With the development of the automotive industry, the demand for auto parts is increasing, and a variety of different manufacturers and suppliers are also springing up. The processing of auto parts is one of them, which can help close to customer needs and meet different needs.

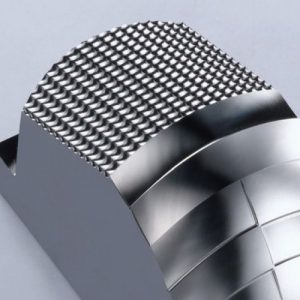

The purpose of auto parts processing is to produce various parts and components related to automobiles in order to repair or upgrade automobiles. Processing usually includes sheet metal processing, forging processing and plastic forming and other processes. Among them, the most common is sheet metal processing, its raw materials are mainly sheet metal, common processing processes are cutting, stamping, bending, folding, welding and so on. These processes can produce parts in a variety of different shapes and sizes, such as body, hood, door panels, etc.

In addition to sheet metal processing, auto parts processing also includes forging processing. This machining is usually used to manufacture larger iron parts, such as engines, transmissions, etc. The process of forging is to heat the metal material to a high temperature state and change its shape through pressure and extrusion. Because the advantages of this process are high strength and durability, forging is often an ideal choice when heavy load parts need to be borne.

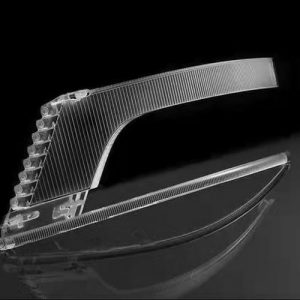

Finally, plastic molding is another common process for automotive parts processing. Plastic molding is characterized by short manufacturing cycle, low cost, light weight and other advantages. As a result, many car manufacturers have listed it as a primary production method. Plastic molding can produce a variety of different parts, such as door handles, instrument panels, wheel hubs, and more.

In general, auto parts processing is one of the necessary processes to achieve automobile production and maintenance. With the continuous development and innovation of technology, the quality and efficiency of auto parts processing are also constantly improving. For auto parts processing enterprises with a high degree of automation, you can improve production capacity and production efficiency through more accurate and efficient production methods, reduce costs and production cycles.

With the continuous development and progress of the automobile industry, auto parts, as one of the important components of the automobile, are also getting more and more attention. Auto parts refer to various parts or parts required for the production or use of automobiles. Auto parts processing refers to the process of various processing, processing and repair of auto parts, including lathe processing, milling processing, welding processing, stamping processing and so on.

Auto parts processing plays a vital role in the entire automotive industry. For car manufacturers, a large number of auto parts are needed to meet the needs of different models of cars. For the maintenance, service industry, auto parts processing is more important. With the increase of car ownership, the demand for automobile maintenance market is also increasing. Therefore, the market prospects of the auto parts processing industry are very broad.

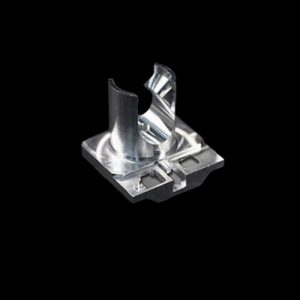

The auto parts processing industry needs to have certain technology and equipment. The most basic piece of equipment is the lathe. A lathe is a machine tool that can rotate workpieces. It is usually used to manufacture various shaft or round parts. In the processing of auto parts, lathes are widely used. In addition, auto parts processing also needs other equipment, such as milling machines, drilling machines, punching machines and welding machines.

Auto parts processing requires certain technologies, such as cutting, milling and punching. These techniques need to be operated by professional technicians. At the same time, auto parts processing also needs to have a certain design ability. In this way, differentiated production and processing can be carried out according to different car models and use conditions, and the safety and stability of the auto parts produced can be ensured.

Overall, the auto parts processing industry has broad market prospects and development prospects. However, auto parts processing enterprises need to continuously improve equipment and technology, and constantly improve their production and processing capacity. At the same time, enterprises also need to pay attention to product quality and safety to ensure that the products produced can meet the needs of customers and are recognized by the market.

Dongguan Lianda professional engaged in auto parts five-axis linkage processing for many years, welcome the need of friends to call for detailed discussion!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers