The automobile industry is one of the most important industries in the world, and the processing of automobile parts is an indispensable part of the industry. Auto parts processing refers to the process of manufacturing, processing, assembly and other operations of auto parts. With the continuous upgrading of automotive technology, the requirements of automotive parts processing are also getting higher and higher, and advanced technology and equipment need to be used to ensure the production of high-quality automotive parts to meet the needs of the market and consumers.

The steps of auto parts processing generally include the following aspects:

The first step is the selection of materials needed to manufacture the parts. Before the processing of auto parts, it is first necessary to select the materials needed to manufacture the parts. According to different auto parts requirements, the material choice is not the same.

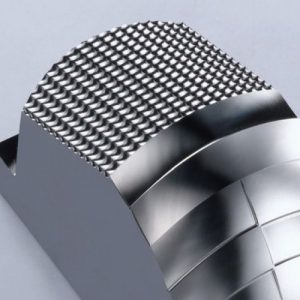

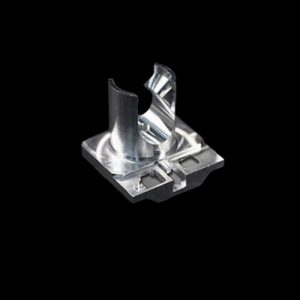

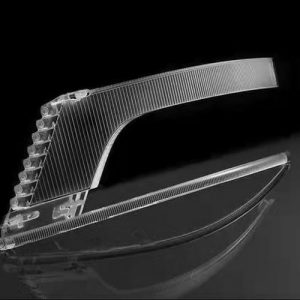

The second step is processing. Today, automotive parts processing mainly uses CNC machine tools, laser cutting equipment, 3D printing equipment and other advanced processes and equipment to ensure the accuracy and quality of parts.

Step three: Assemble. Assembly is the process of assembling multiple parts into a complete car part. This step needs to be done in the operation room of the plant and requires multiple processing processes to cooperate.

The fourth step is detection. The calibration cycles and methods of auto parts are different, but they are all based on accuracy and reliability. For example, X-ray detection technology, infrared imaging systems, laser tracking and other ways to ensure the stability, safety and durability of parts.

Automotive parts processing needs to use high-precision machines and equipment to ensure the quality and function of the parts. At present, there are many manufacturers specializing in the production of auto parts processing equipment on the market, such as domestic Wuzhou machine tool, Jiangsu Blue Shield machine tool, Guangzhou CNC and so on.

In short, automotive parts processing is a crucial link in the automotive industry, and it is also one of the highest revenue areas in the automotive industry. With the continuous expansion of the automotive market, the automotive parts processing industry will also progress.

Auto parts processing is a high-precision, high-tech processing process, its importance and key is self-evident. Modern cars are made up of thousands of parts, and many factors need to be taken into account when designing and manufacturing these parts, such as materials, machining processes, precision, durability, appearance and so on.

In the processing of automotive parts, the materials used usually include steel, aluminum, cast iron, brass, etc. The processing process should be selected according to the specific parts, such as sheet metal parts need to use cutting, punching, folding, welding and other processes, while casting parts need to use casting, polishing, processing and other processes. In addition, in order to ensure the accuracy and quality of the machined parts, professional machine tools and tools are usually needed.

The purpose of auto parts processing is to produce parts that meet the design requirements and have good performance and quality. Some of the key factors to pay attention to during processing include:

1. Selection of materials: The selection of materials plays an important role in the quality and performance of parts. Factors such as strength, toughness, wear resistance and corrosion resistance need to be taken into account when selecting materials;

2. Selection of processing technology: The selection of processing technology should be determined according to the material, shape and design requirements of the parts. Factors such as the required precision, processing difficulty and construction period need to be taken into account;

3. Choice of machine tools and tools: The choice of machine tools and tools has a crucial impact on processing accuracy and efficiency. The appropriate machine tools and tools need to be selected according to the specific processing process;

4. Control of processing accuracy: the processing of automotive parts needs to ensure high precision, so the processing error needs to be controlled in the processing process to ensure that the processed parts meet the requirements.

In general, automotive parts processing is a very complex process that requires a comprehensive consideration of several factors. When manufacturing high-quality automotive parts, engineers need to understand a lot of knowledge about materials, manufacturing processes, machine tools and tools, and processing errors to ensure the production of automotive parts with high dimensional accuracy, stable performance, and good durability, and contribute to the development of the automotive industry.

Dongguan Lianda professional engaged in auto parts five-axis linkage processing for many years, welcome the need of friends to call for detailed discussion!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers