Connector precision machining

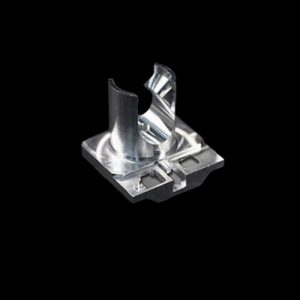

Connectors are essential components in electronic products, and the quality and precision of connectors directly affect the performance and stability of the entire electronic product. Connector precision machining is an important link in connector processing, its purpose is to ensure the process accuracy and product quality of the connector.

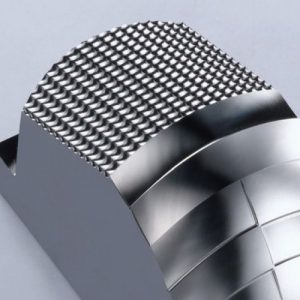

The key to connector precision machining is the use of high-precision processing equipment and advanced processing technology. The precision and stability of precision machining equipment will directly affect the processing accuracy of the connector, therefore, it is necessary to choose high-quality equipment to ensure the accuracy of processing. At the same time, the design and optimization of the processing process is also one of the key factors to ensure the quality of the connector.

The process of connector precision machining generally includes the following steps:

1. Material preparation: The raw materials used for connector processing are generally metal or polymer materials, and the selection of materials should be selected according to the use environment and requirements of the product to ensure the coordination and durability of the material.

2, the choice of processing machine tool: the processing process of the connector needs to use high-precision processing equipment, common equipment are radar lathes, universal grinding machines, CNC milling machines, etc., these equipment can achieve high-speed, high-precision processing.

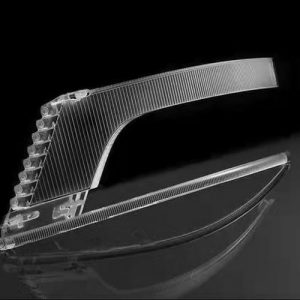

3. Numerical control programming: During the processing of the connector, it is necessary to achieve the accuracy of the processing through numerical control programming, and the programming should be comprehensively considered according to the actual shape of the machined parts to ensure that every detail is correctly machined.

4. Equipment debugging and processing trial production: the equipment needs to be debugging before processing to ensure the normal operation of the equipment. At the same time, it is necessary to carry out processing trial production to verify the rationality and accuracy of the processing process.

5. Quality inspection: After the connector processing is completed, the appearance, size and mechanical properties of the connector need to be comprehensively tested to ensure that the product can meet customer requirements and product specifications.

In summary, connector precision machining has a very important impact on the performance and stability of the connector. It is not only necessary to have high-precision processing equipment and advanced processing technology, but also to pay attention to the details of the relevant operation and quality control to ensure the processing accuracy and product quality of the connector.

Connector is a basic electronic component, is an important connection tool in electronic circuits. It is widely used in computer, communication, home appliances, automobiles, medical equipment and other fields. With the continuous popularization and development of electronic products, the application of connectors is becoming more and more extensive, and the requirements for accuracy and reliability are becoming higher and higher. Therefore, the precision machining technology of connectors is increasingly important.

The processing of connectors involves a number of links, including the selection of raw materials, the design of processing technology, and the construction of production lines. Among them, the selection of raw materials plays a crucial role in the quality of the connector. Commonly used materials are copper, titanium, aluminum and other metal materials, ceramics, plastics and other non-metallic materials. In the selection of materials, it is necessary to pay attention to the conductivity, plasticity, strength, chemical properties and other factors of the material, and consider the hardness, conductivity and other characteristics required for processing.

In the processing of connectors, some special processes and equipment need to be used, such as CNC machining machines, lithography machines, electric etching machines, etc. These devices can provide high-precision machining and high-speed machining capabilities, and can be designed and adjusted according to the requirements of the connector. For example, for some high-precision connectors, it is necessary to butt at the micron level, at which time it is necessary to use a micromachining process, combined with the lithography process and thin film technology for processing.

In addition, the standardization and automation of manufacturing connectors are also important aspects of connector precision machining. Standardization can make the connector production process more standardized and reduce errors and losses in production. Automated production lines can achieve high efficiency production of connectors, improve production efficiency and connector quality.

In general, connector precision machining technology plays an important role in modern communications, computers, automobiles, medical and other fields. With the continuous development of electronic products, connector precision machining technology is also constantly improving and improving. In the future, connector precision machining technology will be more intelligent, standardized and efficient, providing better support for the development and innovation of electronic products.

Dongguan Lianda focus on five axis precision machining for many years, rich experience, welcome the need of friends to call for detailed discussion!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers