Military parts processing is a high precision, high quality requirements, high-tech processing business, is an essential part of the military industry. With the development of the military field, the demand of the military industry is getting higher and higher, and the processing of military parts is gradually widely used in various aviation, aerospace, navy and other fields. Therefore, military parts processing has also become one of the important areas of competition for major enterprises.

The complexity of military parts processing is mainly manifested in the following aspects:

First, processing requires high precision

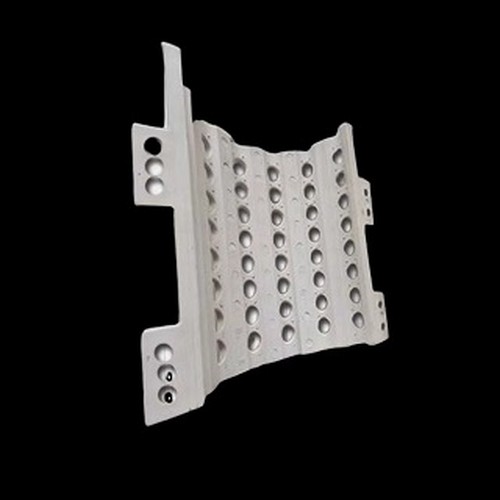

The precision of military parts processing is extremely high, especially for the manufacture of high-tech weapons and equipment, such as fighter jets, missiles and quantum radars, and the processing accuracy is in the micron range. In order to meet such requirements, the manufacturing process and processing technology need to reach the corresponding level. The processing equipment must have high precision, high stability and high automation level, and the operator must be professionally trained to be competent for this technical work.

Second, the material requirements are high

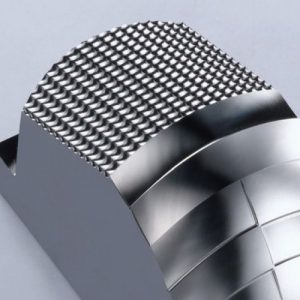

The material requirements of military parts processing are very strict, requiring materials with high strength, high corrosion resistance, high fatigue resistance and other characteristics. These materials are not only difficult to process, but also expensive, which brings great challenges to the processing process.

3. Short manufacturing cycle

Combat equipment such as warplanes and missiles in the military industry are usually used at critical moments, so the production cycle is very short, requiring manufacturers to complete production tasks quickly and efficiently. Every link in the production line must ensure precision, quality and efficiency.

Fourth, high safety requirements

The center of military parts processing is the manufacture of combat weapons, so the safety requirements in the production process are very high, and it is necessary to ensure the safety and reliability of the manufacturing process and the safety of production personnel. At the same time, the manufacturing plant of military parts processing must comply with the relevant laws and regulations and pass the strict review of the relevant departments.

In general, military parts processing is a very challenging job that requires highly skilled workers, highly efficient manufacturing processes and highly stable equipment. At the same time, we must also consider the need to ensure quality and safety and reliability, which for military enterprises and manufacturers need to have a certain amount of experience and technical strength. The military industry should constantly improve and improve its processing technology to meet the development needs of the military and the army, and make more contributions to the development of the military industry.

With the continuous progress and development of military technology, the importance of military parts processing is becoming more and more prominent. Military parts, as an indispensable part of military equipment, are crucial to ensure the reliability and accuracy of equipment. The processing of military parts has high precision requirements, complex processes, and high machine and equipment requirements, which makes it different from ordinary mechanical processing, so the processing of military parts has a high technical content and difficulty, and requires more detailed and meticulous operation.

The technical requirements of military parts processing mainly include the following aspects:

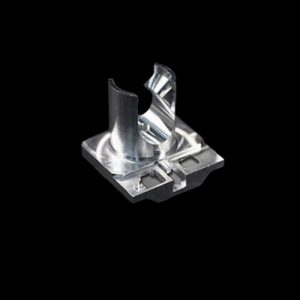

First of all, military parts processing needs to improve production efficiency. Military equipment is usually produced in large quantities, so the processing productivity needs to be greater than a single number of parts. To this end, efficient equipment and advanced processing technology should be used to achieve high efficiency and quality processing.

Secondly, military parts processing requires high precision. The working environment of military equipment is usually very bad, even extremely bad. The precision and accuracy of parts processing directly affect the reliability and service life of the equipment, so the precision of military parts processing is higher. At the same time, military parts usually have high precision requirements, so high-precision equipment and processes must be used for processing.

Thirdly, the processing of military parts needs to fully consider the material properties. The mechanical properties and thermal properties of different materials are different, and the corresponding processes and equipment should be used for the processing of different materials to ensure the processing quality and accuracy.

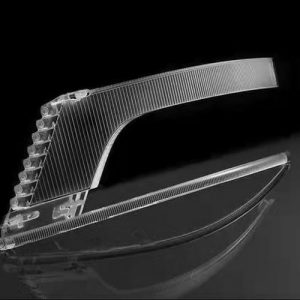

Finally, military parts processing needs to ensure the sealing and durability of parts. Military equipment is usually used in extremely harsh environments, such as under water, high altitude, low temperature, high temperature, etc., so the sealing and durability of the parts must be guaranteed. To this end, the processing technology with excellent materials, fine technology and strict detection should be used to ensure the quality and performance of the parts.

In short, military parts processing is a very important task, which is crucial for national defense construction and security. In the processing process, it is necessary to pay attention to improve production efficiency, ensure processing accuracy, consider material characteristics, and ensure the durability and sealing of parts. Continuous innovation and improvement in technology and equipment can better ensure the stability and reliability of the quality of military equipment.

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers