Shenzhen five-axis linkage processing/five-axis linkage processing which is good

Shenzhen is one of the fastest growing areas of domestic manufacturing industry, and it is also one of the regions where five-axis linkage processing technology is widely used. Five-axis linkage machining technology is an advanced machining technology, which is widely used in the field of machining. Through the five-axis linkage processing technology, the manufacturing efficiency of parts can be greatly improved, while reducing production costs, improving the precision and quality of products. Shenzhen five-axis linkage processing/five-axis linkage processing which is good? Welcome to consult Lianda Precision!

The application of five-axis linkage machining technology in Shenzhen is very common, and can be applied to the manufacture of various parts, such as aerospace, auto parts, medical equipment, molds, complex curved parts and so on. The manufacturing of these parts requires high-precision processing equipment and high-quality processing technicians, Shenzhen’s five-axis linkage processing enterprises have perfect ability of independent research and development manufacturing processing equipment, but also has many experienced, excellent processing technical personnel, thus providing a strong guarantee for the manufacturing of these high-precision parts.

The application of five-axis machining technology in Shenzhen is also shown in improving production efficiency and resource utilization. Five-axis machining technology can use the flexibility of the machine to achieve all the production operations required for a machine to work, avoiding the time of machine conversion and relocation, and improving production efficiency. At the same time, the five-axis machining technology can realize a variety of operations on a workpiece, which can maximize the use of raw materials, reduce the waste of raw materials, and thus be more environmentally friendly and cost saving.

In general, the application of five-axis linkage processing technology in Shenzhen not only promotes the development of manufacturing industry, but also provides more quality services and guarantees for the manufacturing of high-precision parts, and brings more economic and social benefits to production enterprises. Shenzhen five-axis linkage processing/five-axis linkage processing which is good? Welcome to consult Lianda Precision!

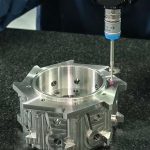

Five-axis machining refers to the use of five axial tool movements to achieve multi-directional and multi-angle machining methods in the processing of complex or curved parts. Compared with the traditional three-axis machining method, the five-axis linkage machining can greatly improve the accuracy and efficiency of parts manufacturing.

In the five-axis linkage machining, the workpiece can move in the three directions of x, y and z at the same time, and can also be rotated in two directions, so the five-axis linkage machining is very suitable for the processing of complex parts. At the same time, the five-axis linkage machining can also complete the processing of complex parts from different angles in the case of a single clamping, and realize the multi-function of a single processing, which greatly reduces the time and cost of production and processing.

Shenzhen five-axis linkage machining has advanced equipment and technology, the use of numerical control system to control multi-axis machine tools for processing, to ensure the accuracy and efficiency of processing. In addition, Shenzhen five-axis linkage machining company also has a perfect quality assurance system, the use of precision testing equipment and professional teams for quality control, to ensure the quality and stability of machined parts.

In short, Shenzhen’s five-axis linkage processing technology has achieved remarkable results in high-precision, high-quality and efficient processing, which will provide strong support and guarantee for the future development of the manufacturing industry. Shenzhen five-axis linkage processing/five-axis linkage processing which is good? Welcome to consult Lianda Precision!

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers

Hardware parts processing 5-axis machining - 5 axis CNC machining - 5-axis linkage machining - five-axis machining price - non-standard hardware machining - precision parts processing manufacturers